F4F/FM2 Wildcat Wing Layout Study

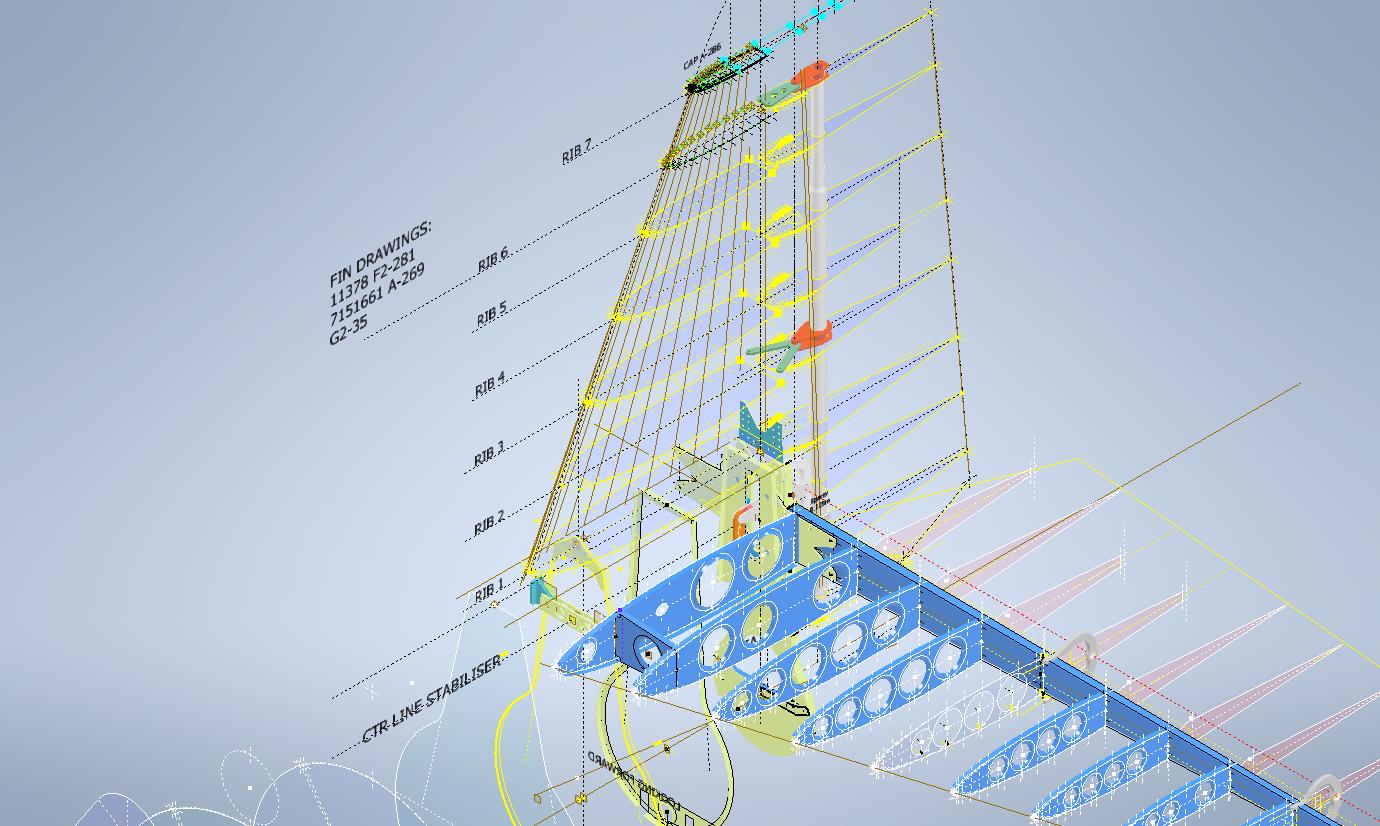

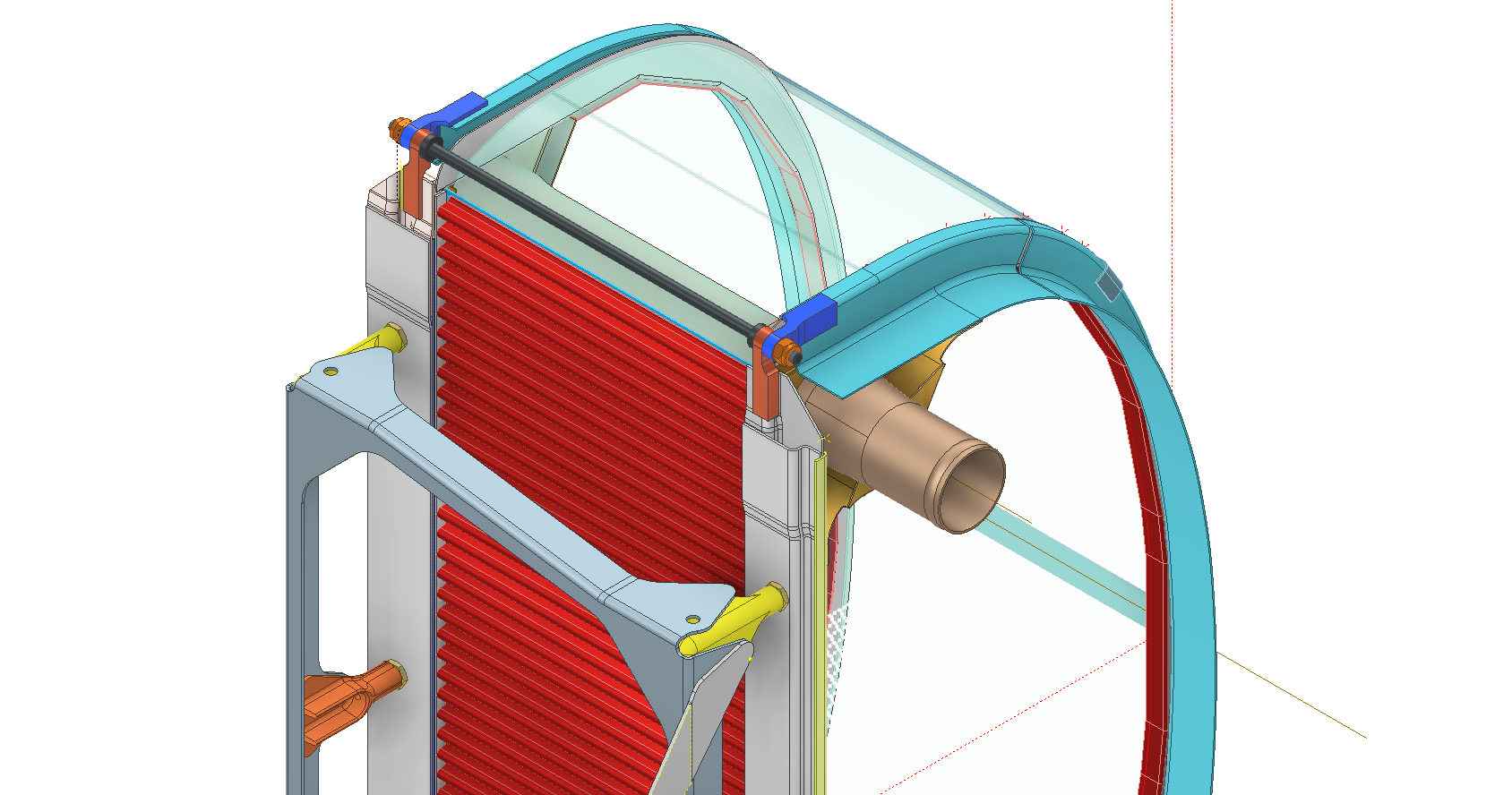

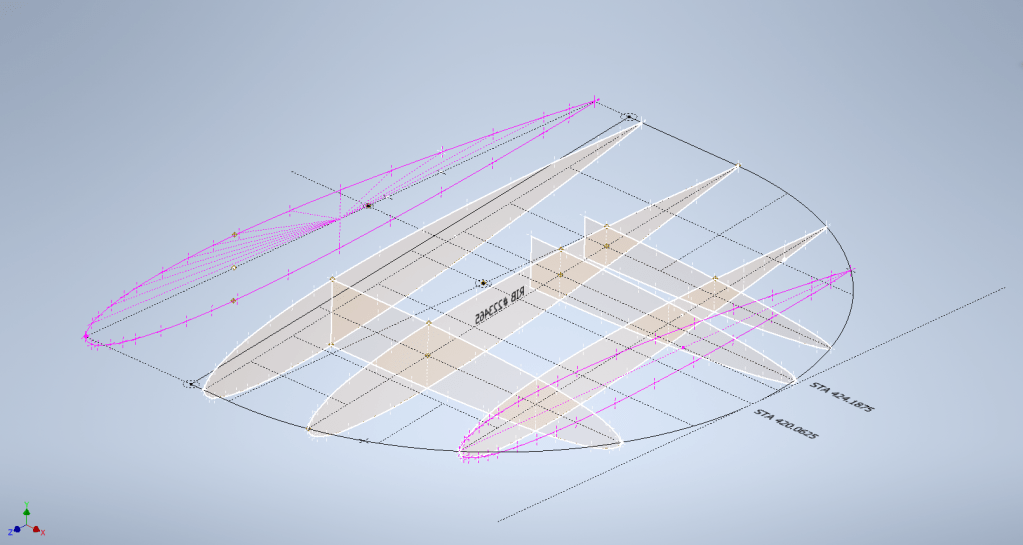

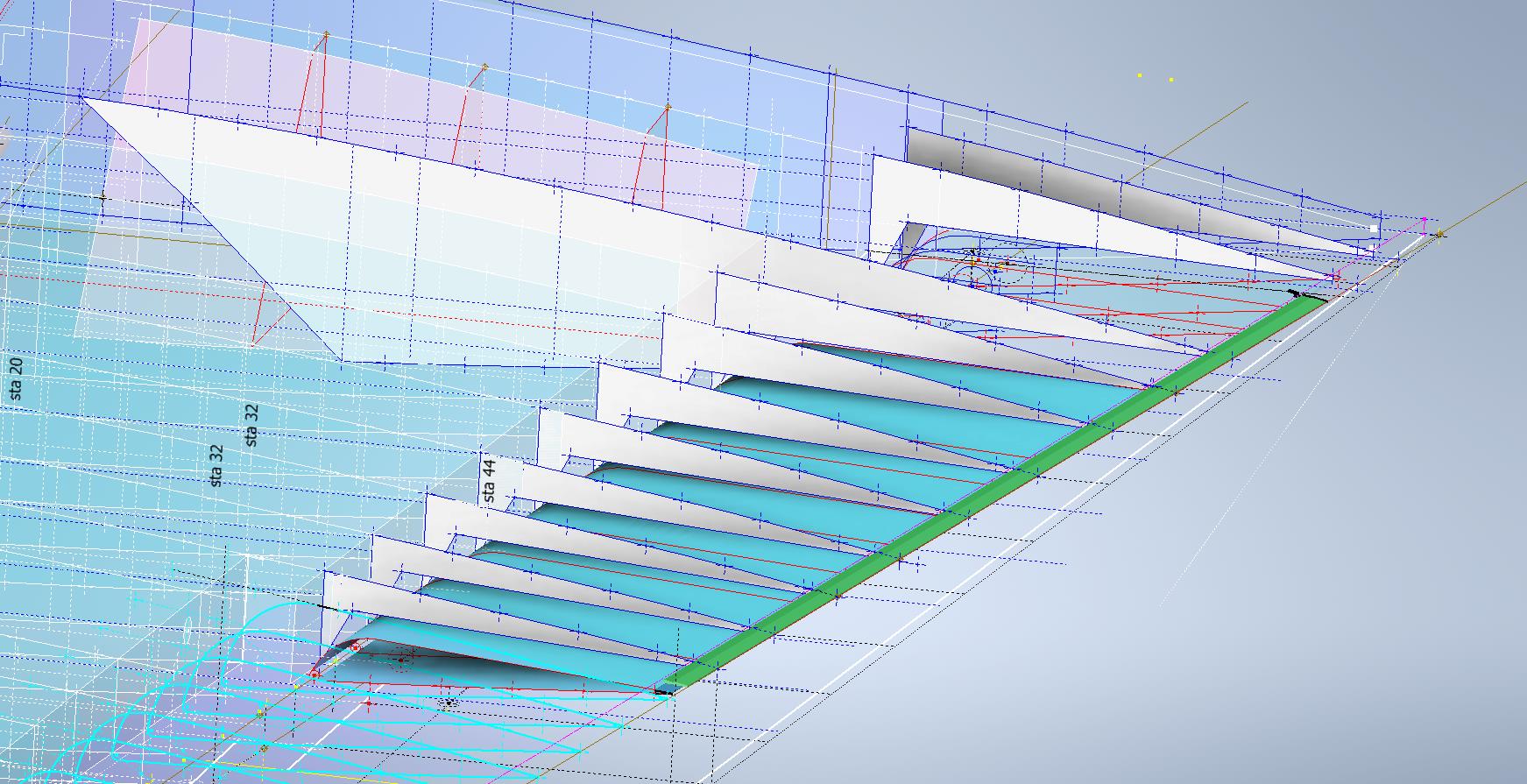

Since my last post, I have further developed the Wing layout which has revealed a number of key considerations that you may be interested in.

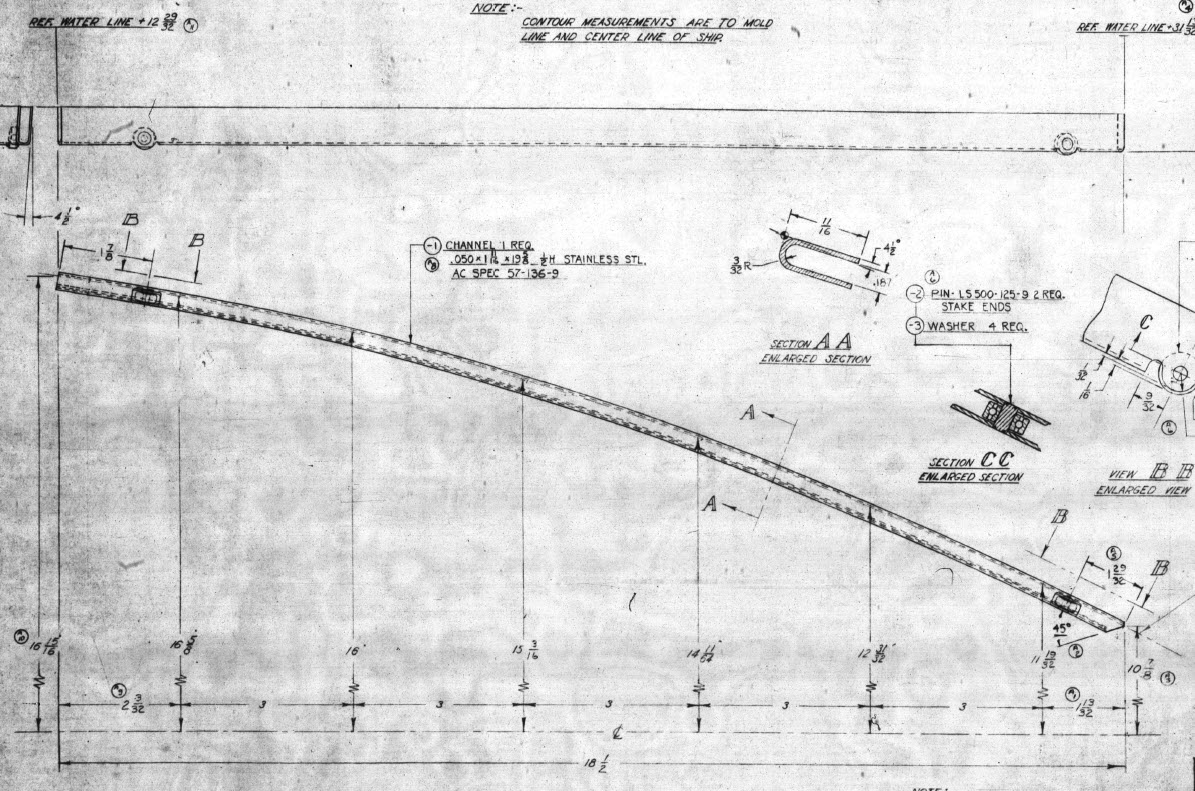

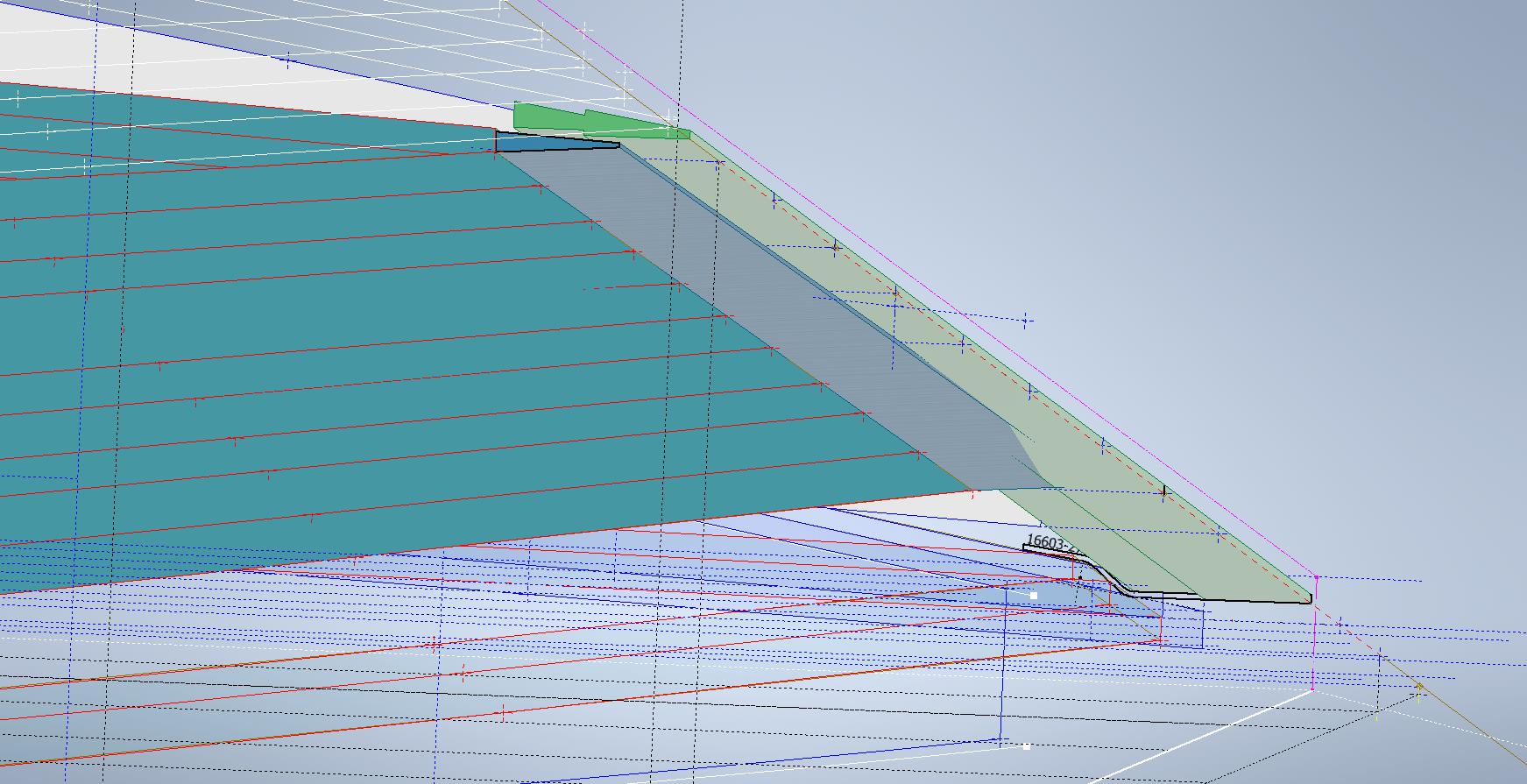

Wing Trailing Edge:

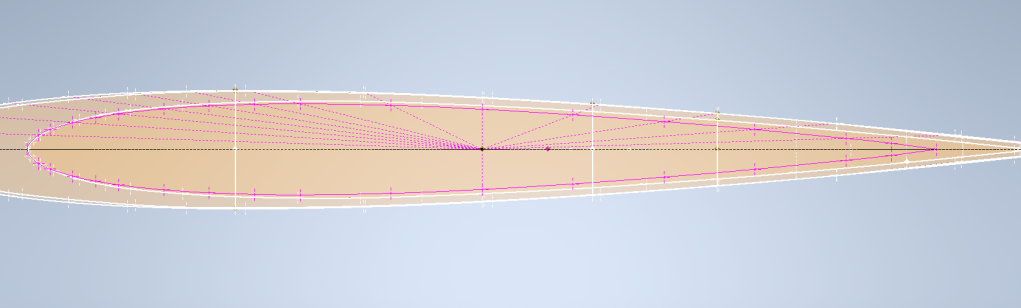

Other than a noted offset on the rib drawings there is no definitive alignment specified for the Wing Trailing Edge. What I found was the Wing Trailing Edge rib profiles were reasonably accurate from which I could determine this alignment.

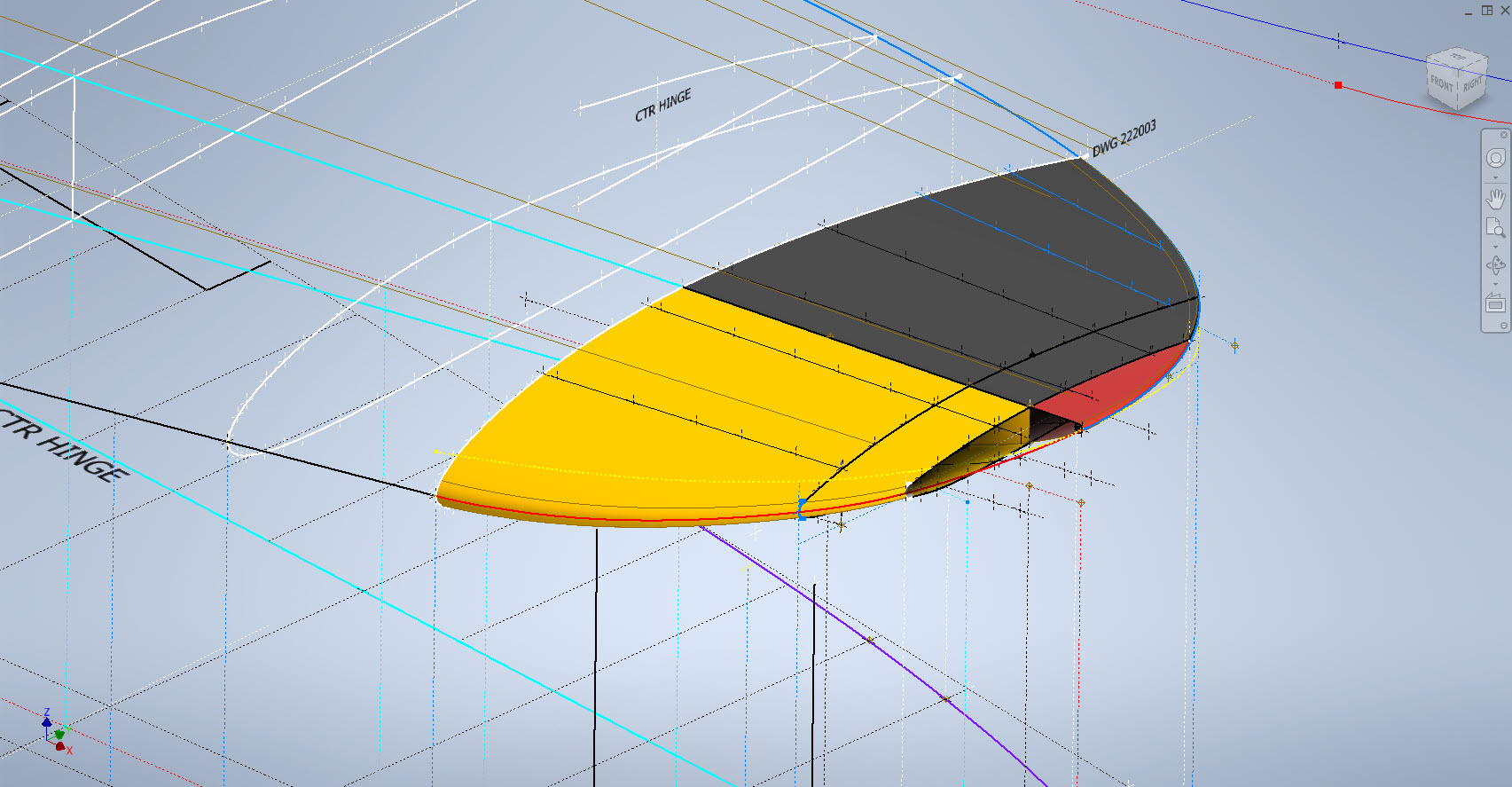

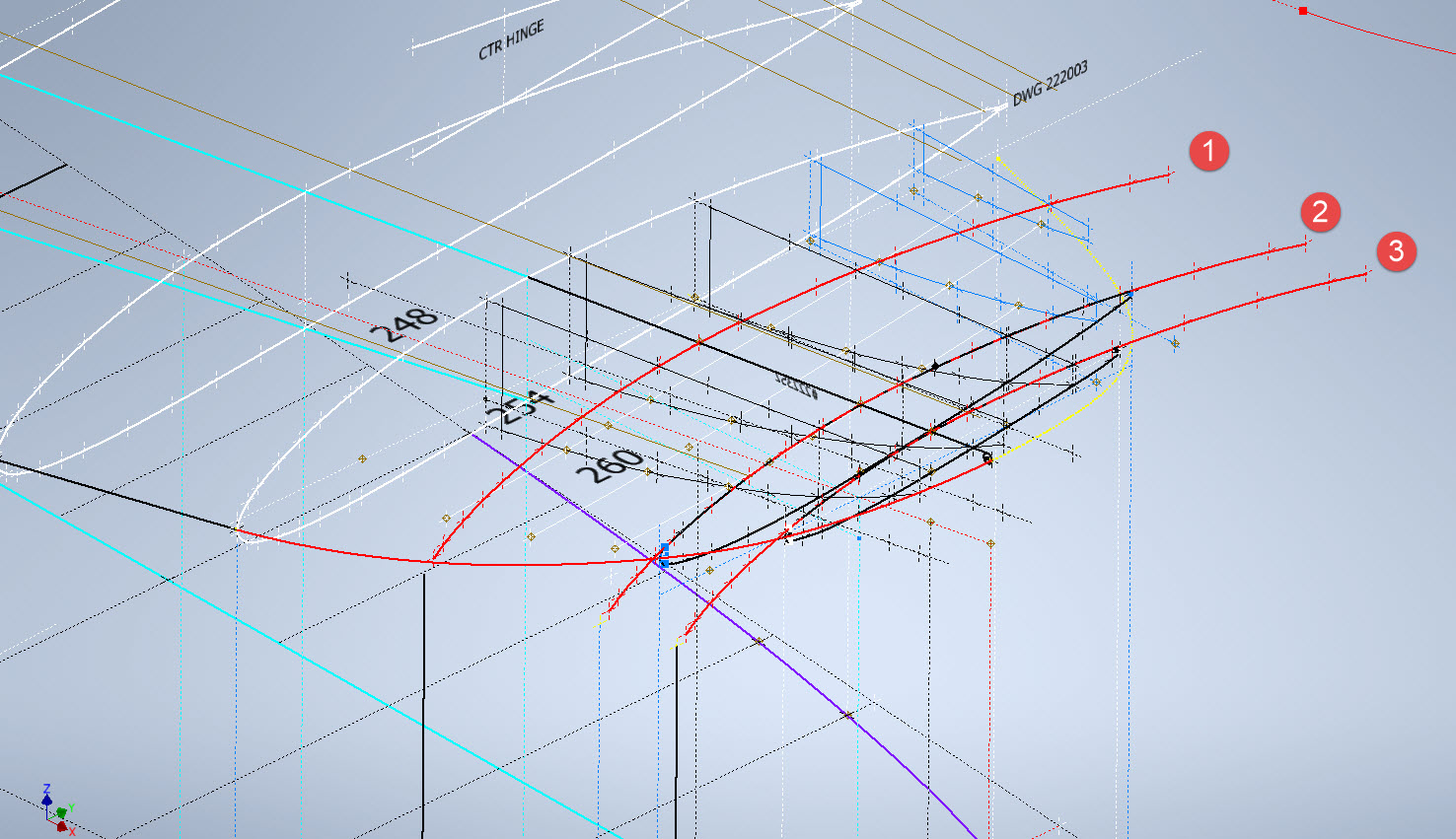

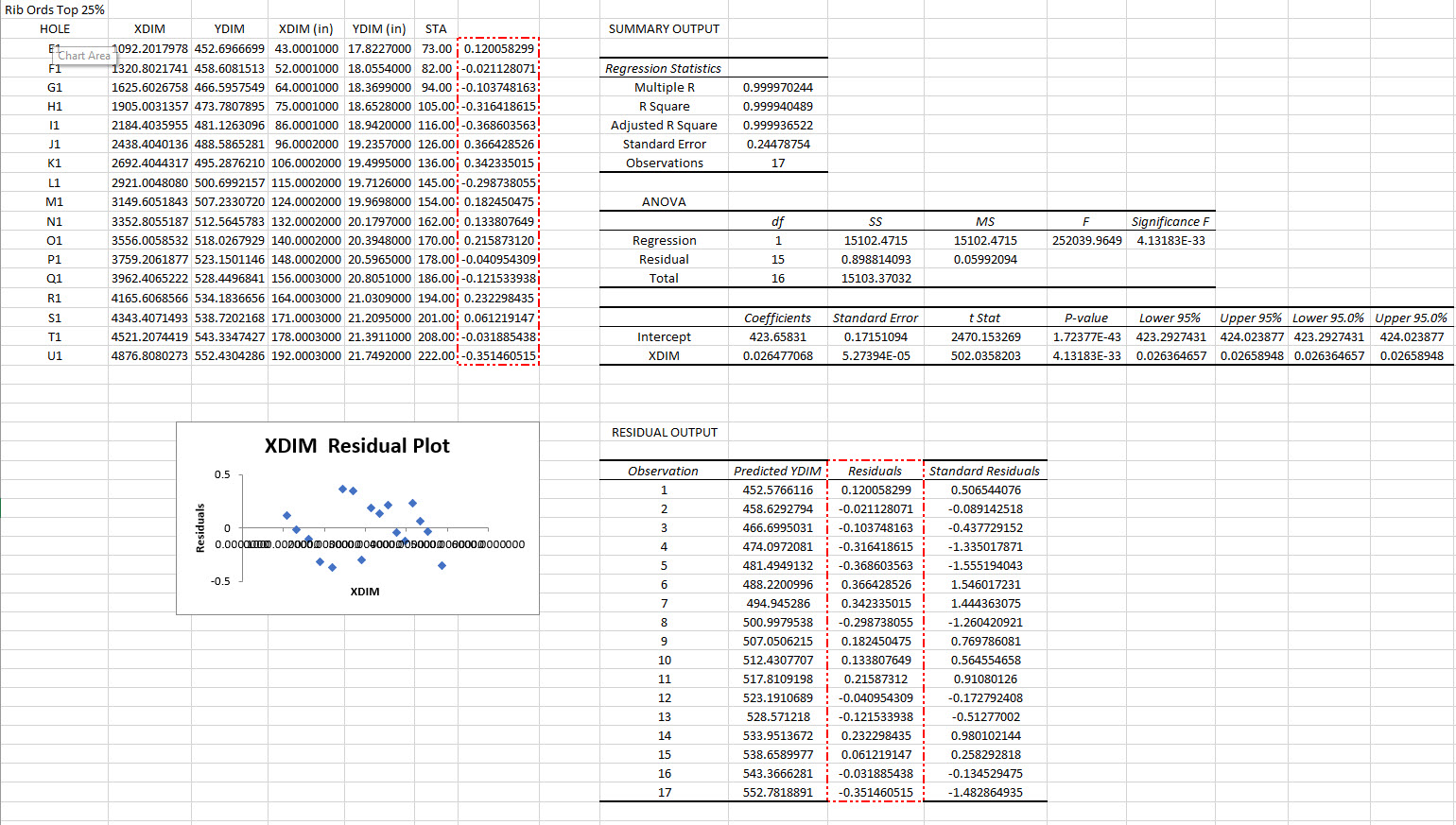

The component shown in green is the Alcoa K14403 standard Grumman profile for the trailing edge. When I developed each of the wing TE profiles (white) there was a minuscule variation in the alignment, so I needed to determine the best-fit line through those points using Linear Regression Analysis. I could just have easily selected 2 random points from the wing TE profiles which would have been okay but I like to get this stuff right.

By using Linear Regression there is no guesswork or random selection it simply analyses the point coordinates and calculates a line that best fits all these known points. As we have 11 coordinate points to analyze the end result will be an accurate placement of a Trailing Edge line that represents the collection of known coordinate points. The column named Residuals is the offset from the known coordinates to this line. As you can see the max offsets are in the region of 0.3mm…well within normal fabrication tolerances.

Having now established a correct Trailing Edge I checked this against the flaps (cyan) to see how well the assembly aligns with this newly defined trailing edge. I noted a deviation of 2.2mm on the outboard edge towards the wing tip.

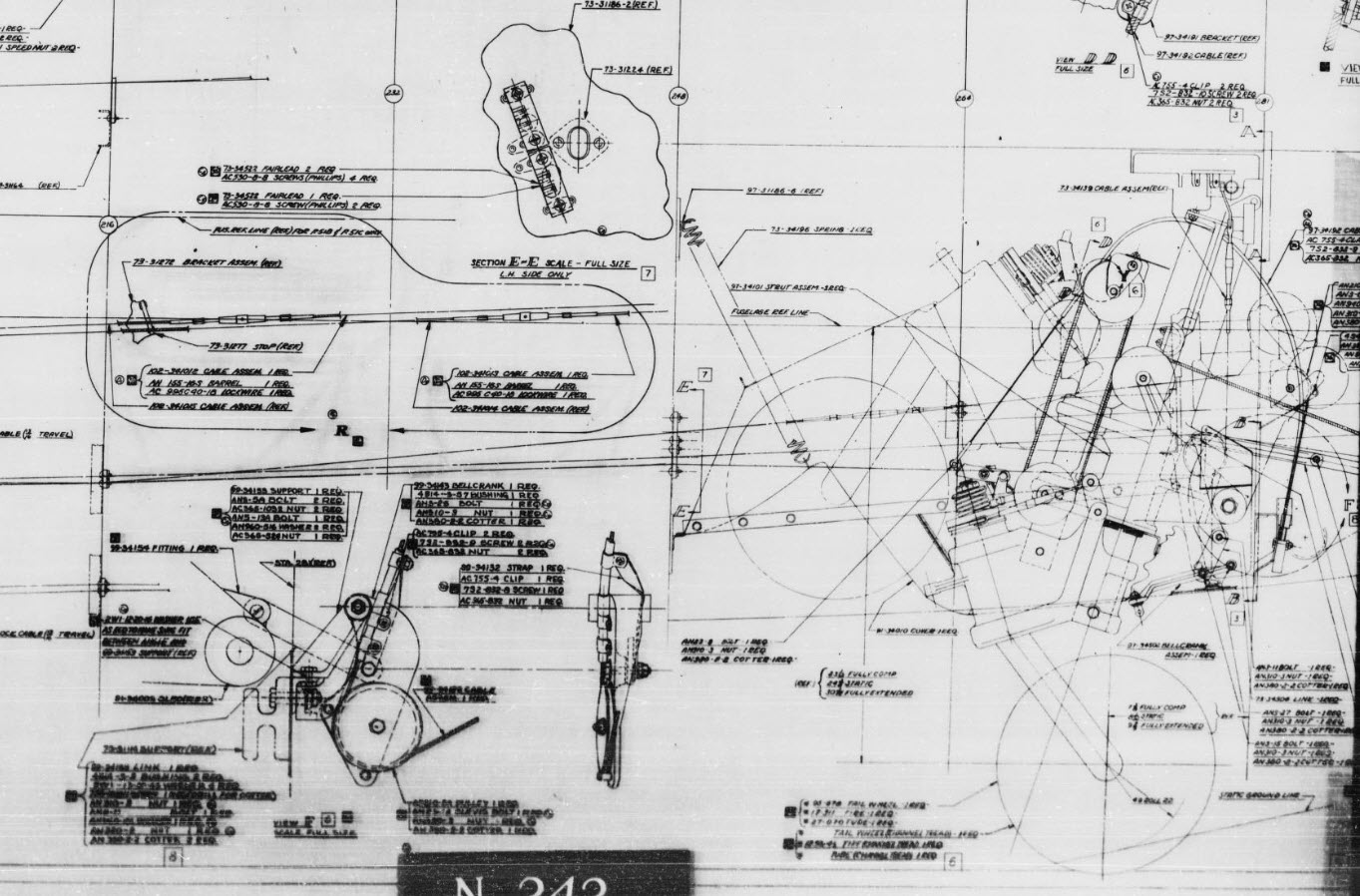

Flaps:

In the image above you can see how the flap assembly does not align exactly with the wing trailing edge. My first impression was that I had made a mistake with the model, so I rebuilt it resulting in the same deviation. So I checked the location of the hinges…they are dimensioned to 4 decimal places of an inch so for all intents and purposes they are exactly located. Further research reveals that there is a return spring on these flaps and I think what is happening is the flap layout is deliberately set out this way so the flap first engages with the wing at the control cylinder end and then the return spring engages closure with the outboard end…hope that makes sense. Grumman has used this type of spring mechanism to engage the closure of wing surfaces elsewhere at the wing folding mechanism.

I believe the geometry for the flaps is correct however my dilemma is whether or not to adjust the alignment to align perfectly for the future purpose of design analysis…and of course should there be any interest in the development of an RC model. One to ponder.

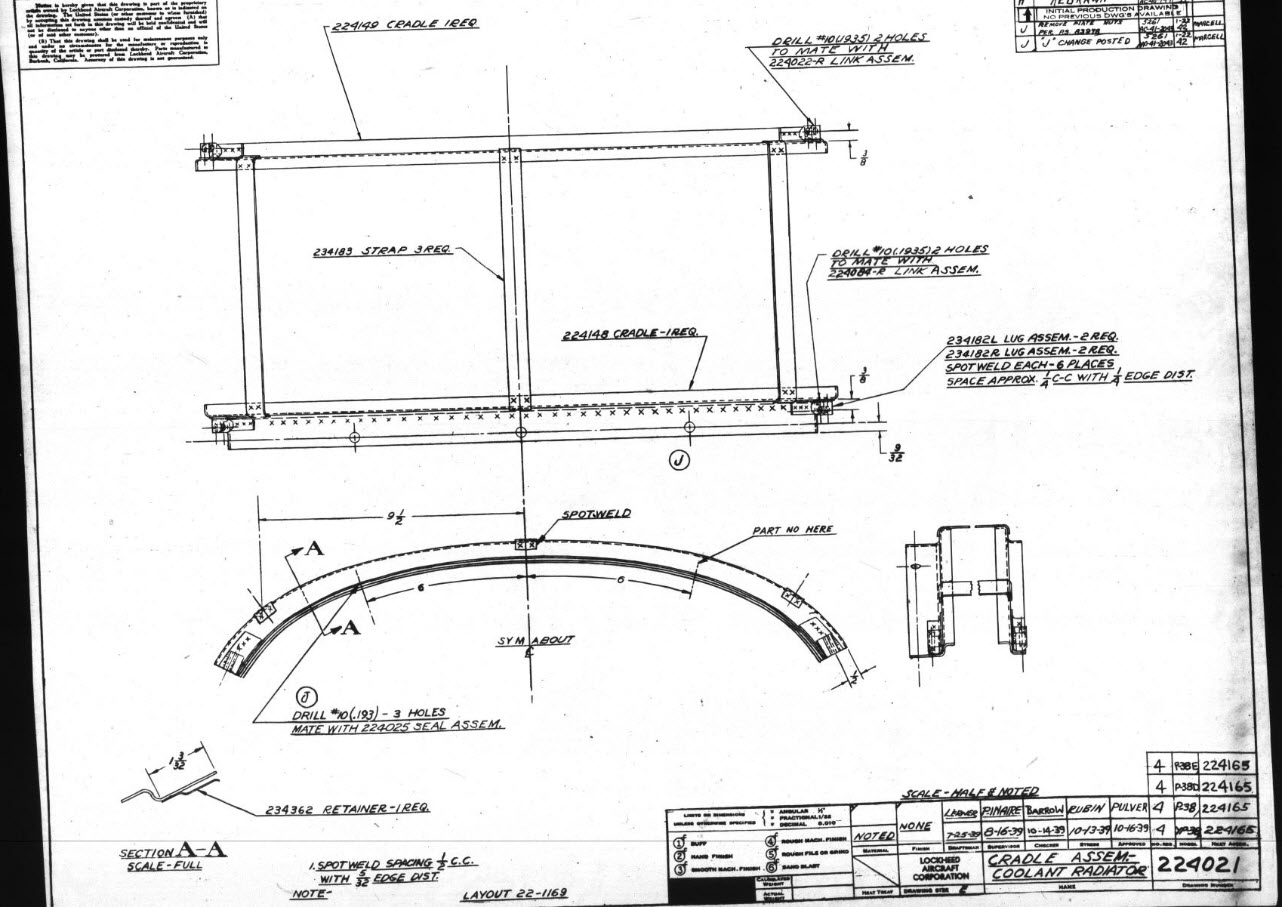

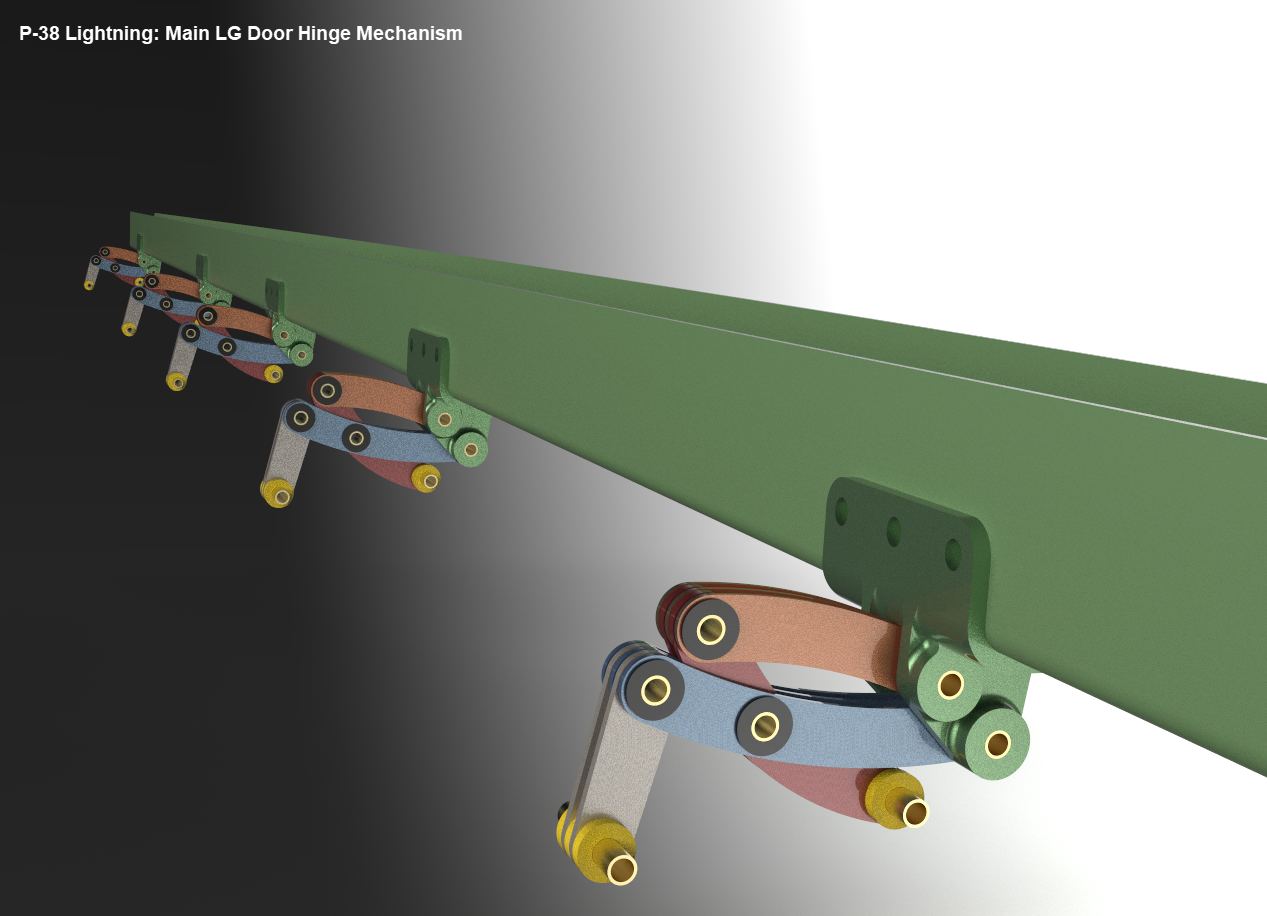

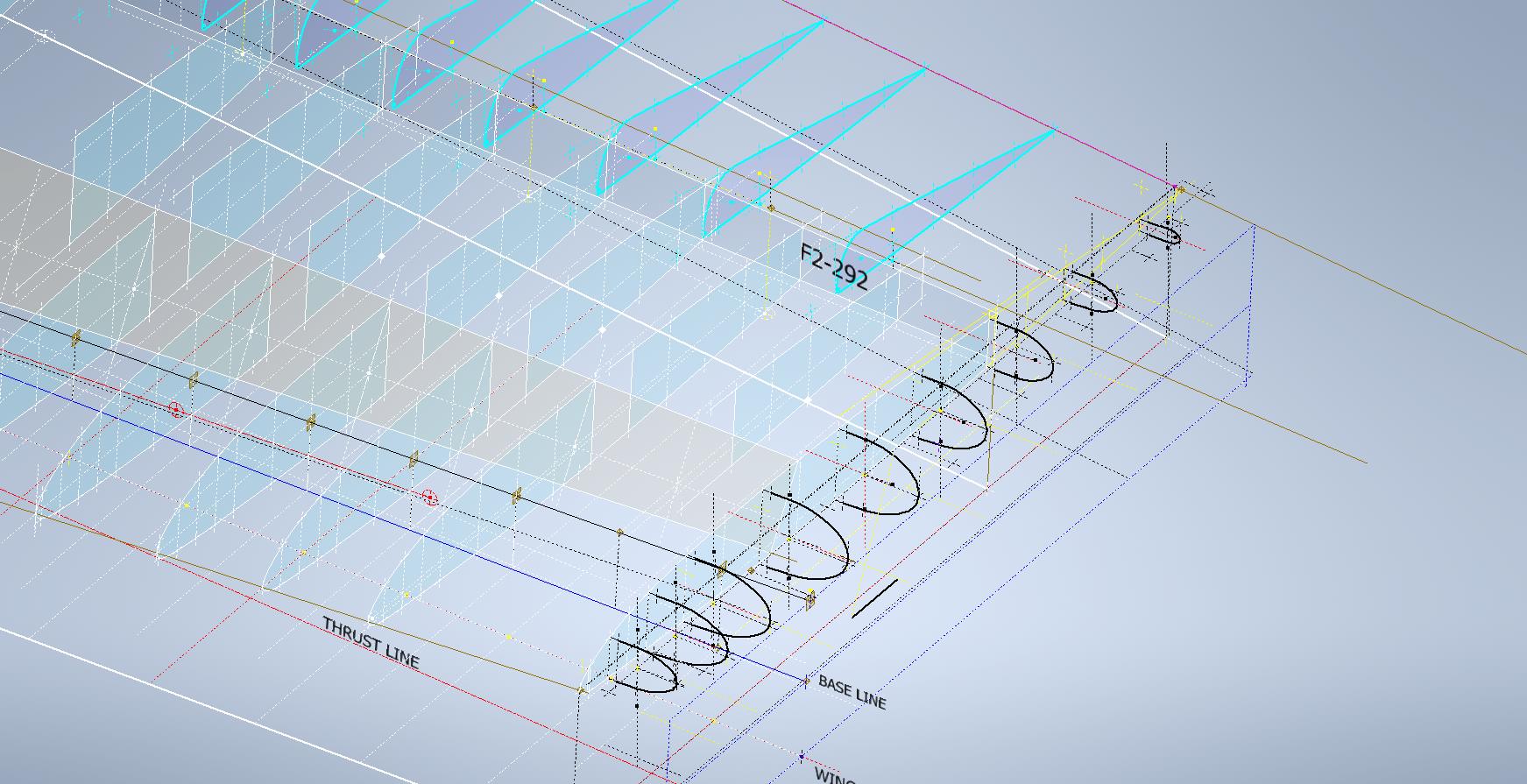

Wing Folding Web:

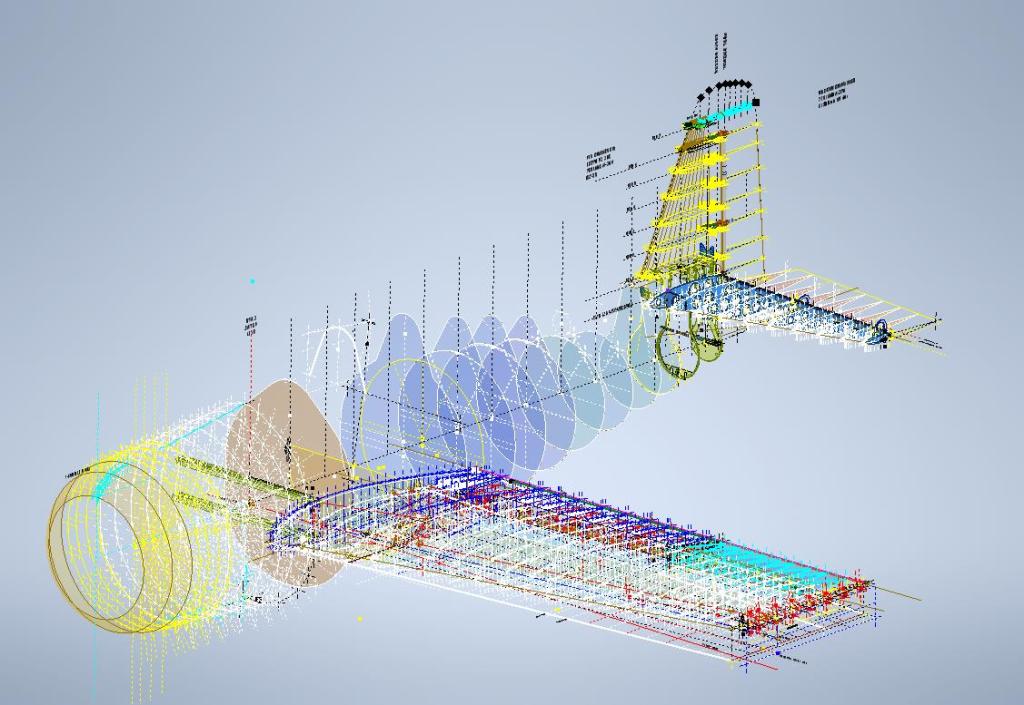

On the inner wing stub section, there is a sloped web plate attached to 3 triangular gussets. This is basically the mating plane for the wing stub and the main wing assemblies at the wing folding joint. This is one area that is not so accurately dimensioned…when you develop the triangular gussets there is a slight variation in the edge slope that this web plate is fitted to and similarly, the profile of the web plate is also marginally out. We are talking about fractions of millimeters but it does matter. I developed this area in a separate assembly where the wing ribs were lofted and then the triangular ribs and web plate were sectioned. Incidentally, the second image above is the only drawing (#7150645) that indicates the slope of this web plate at 50 degrees. You can also see the numerous datum lines that we have for setting out this wing that I mentioned in previous articles.

The mating portion of the outboard wing that engages with this web plate is the spring-loaded assembly I mentioned above…I have yet to do that part…will probably feature in a future article.

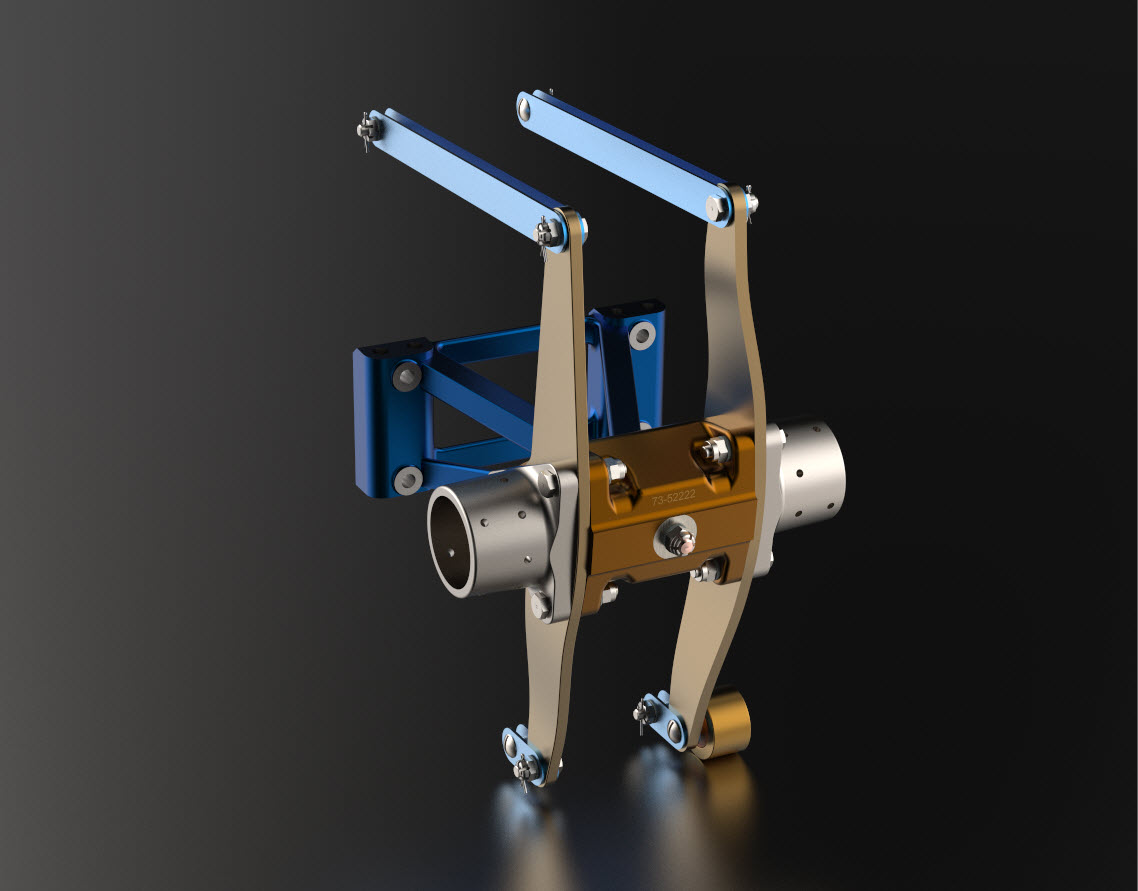

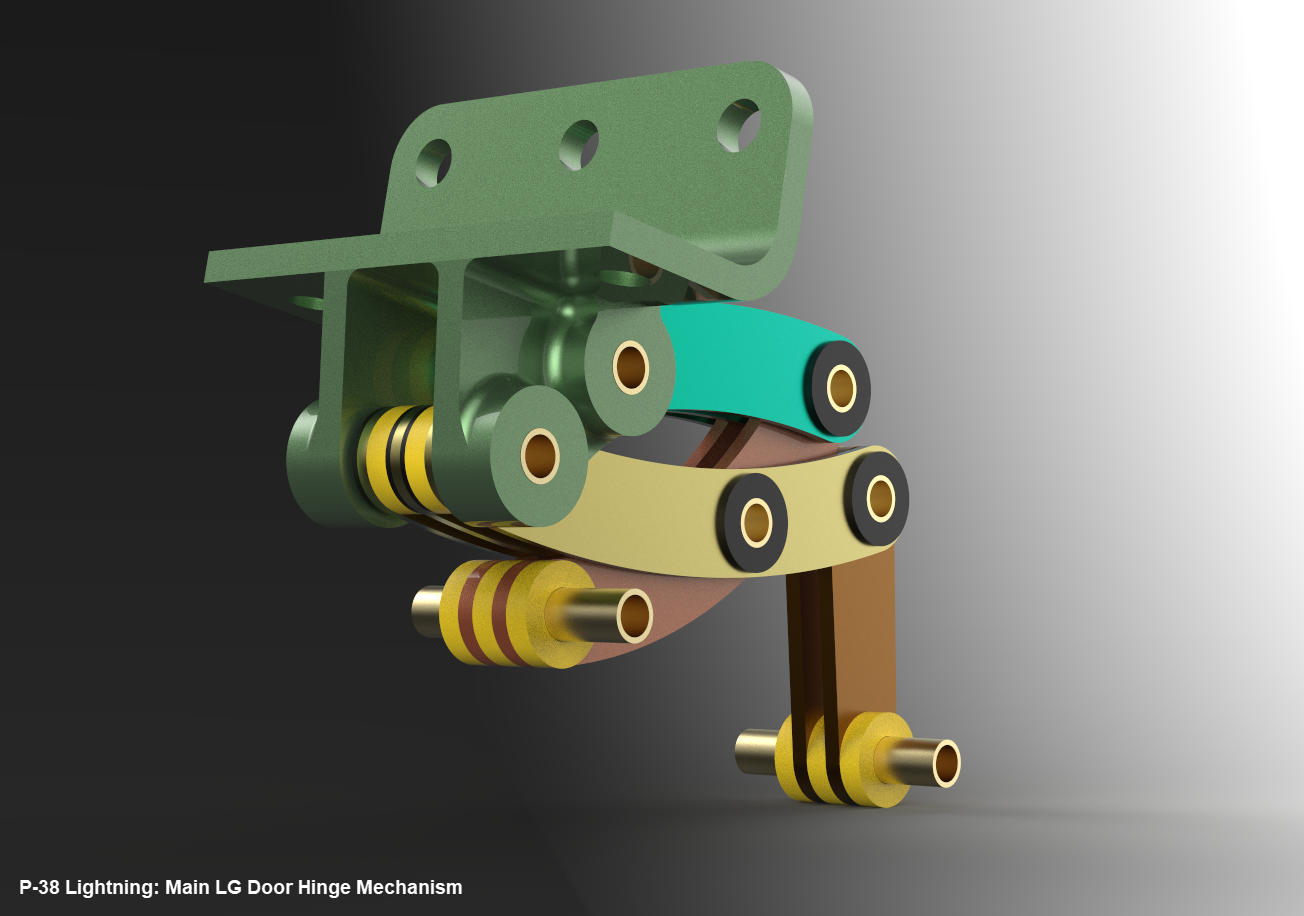

Wing Folding Hinge:

Just a quick update on the Wing Folding Hinge. I have this fully dimensioned now as an ISO View, Front and Side elevations which enables alignment checks with associated ribs and web plates. It is important that the rear face of the main spar aligns with the center of the hinge so these dimensions help establish this correct relationship.

Wing Tip:

The wing tip sketch profiles are now drawn but there appears to be a slight mismatch with the wing tip rib profile at Sta 222. The Trailing Edge at 55/64″ below the Chord LIne was also puzzling as it did not align with the Trailing Edge line mentioned above. Again my first impression was that I made a mistake with the rib profile…drawn again…same result. I then checked the alignment with the Aileron assembly and whilst the wing rib TE aligns with the Aileron TE the Aileron does not align with the Wing Trailing Edge line.

This one is a bit more difficult to comprehend as there is no logical reason for the Aileron to essentially drop toward the Wing tip…yet the wing tip rib and aileron align well. Again I checked the hinge locations and they are exactly where they should be. I have been in touch with a number of museums and restoration companies to see if they have an explanation and also requested photographs along the edge of the aileron to visually examine the aileron alignment. I will get back to you on this one. By the way, I also carried out a linear regression analysis to determine the exact reference line locations for each aileron rib as a check.

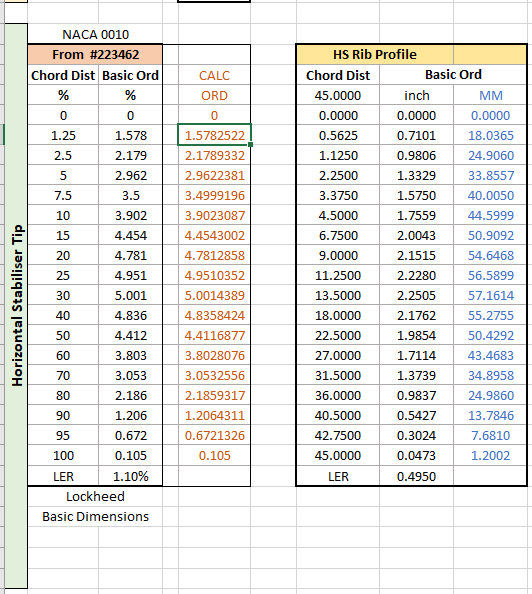

This aircraft is surprisingly complex and whilst there may be perceived anomalies that at first cannot be explained there is usually a good reason for being the way they are. For example, the leading edge of the horizontal stabilizer has a negative camber towards the tip, essentially the leading drops….this is most unusual.

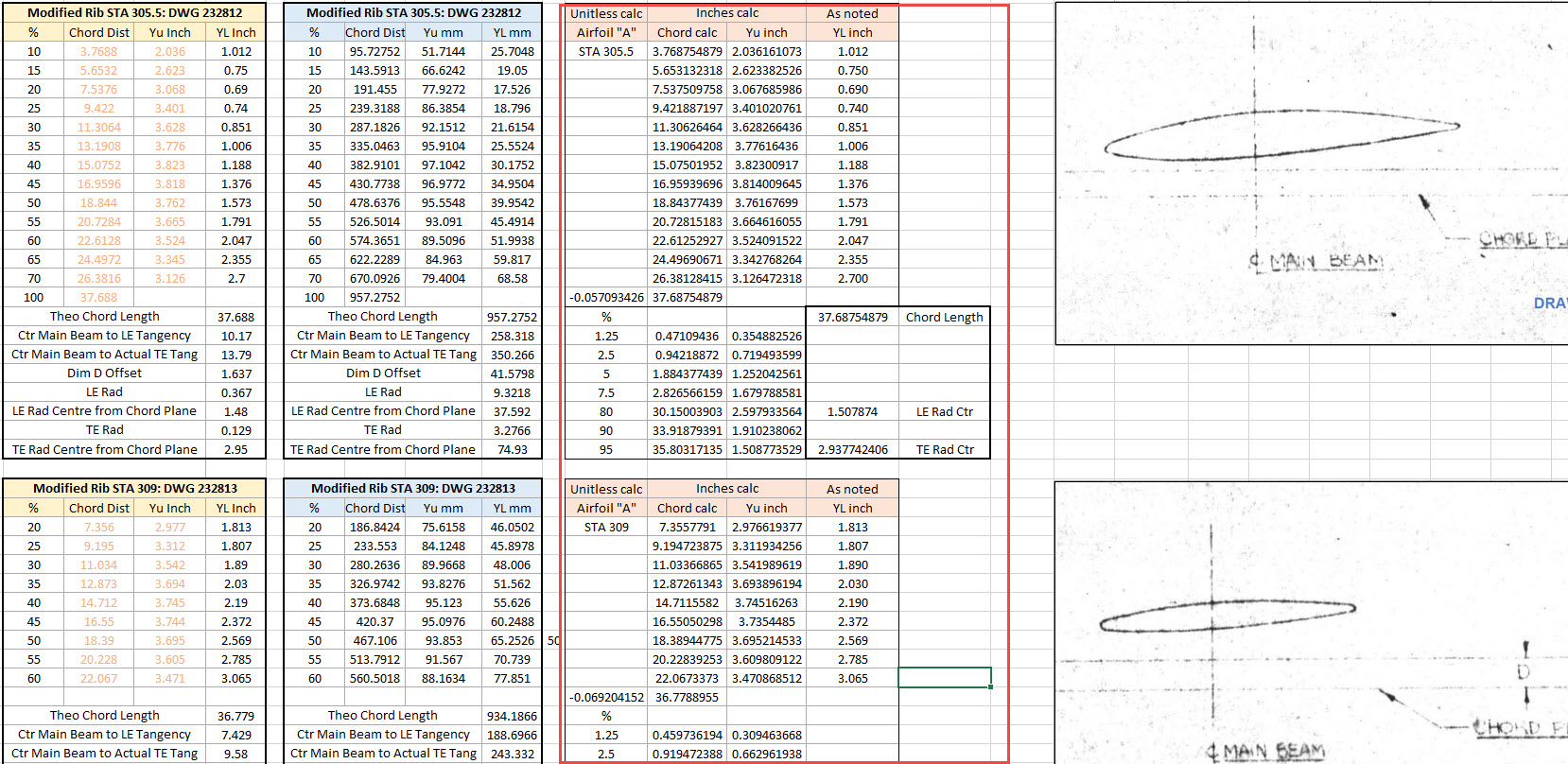

Finally, to make things even more puzzling the wing tip rib profile is not actually a NACA 23009…it is close in profile but it does match exactly…I believe this is a modified NACA 23009. Once I have all the ribs modeled according to the Grumman drawings I will calculate the wing rib ordinates to double-check the profiles…that will be a real pain and time-consuming thing to do as the ordinates are at 4-inch and 2-inch intervals along the chord and not by chord percentage as one would expect…so I need to transpose that data from the cad models to develop the equations for checking.

I have spent an incredible amount of time developing this wing, perhaps more than any other aircraft study I have done. This design is very complex and keeps throwing up small anomalies that at first are difficult to comprehend…it does require a lot of research to figure out the reasons why.

Update 17th Sept 2023:

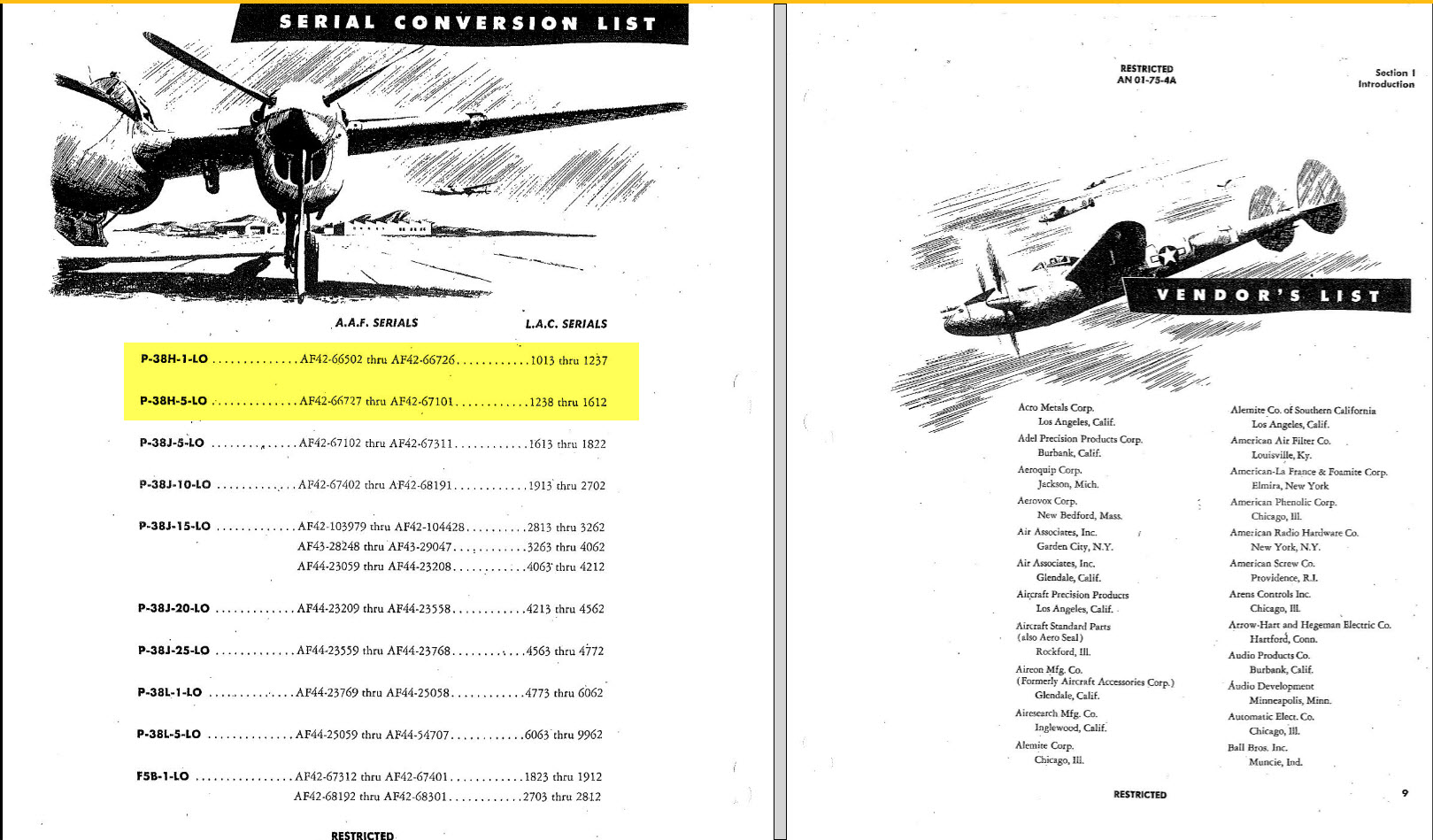

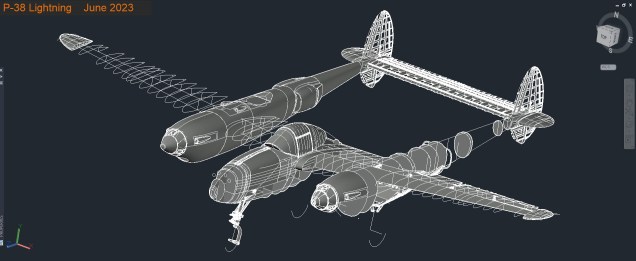

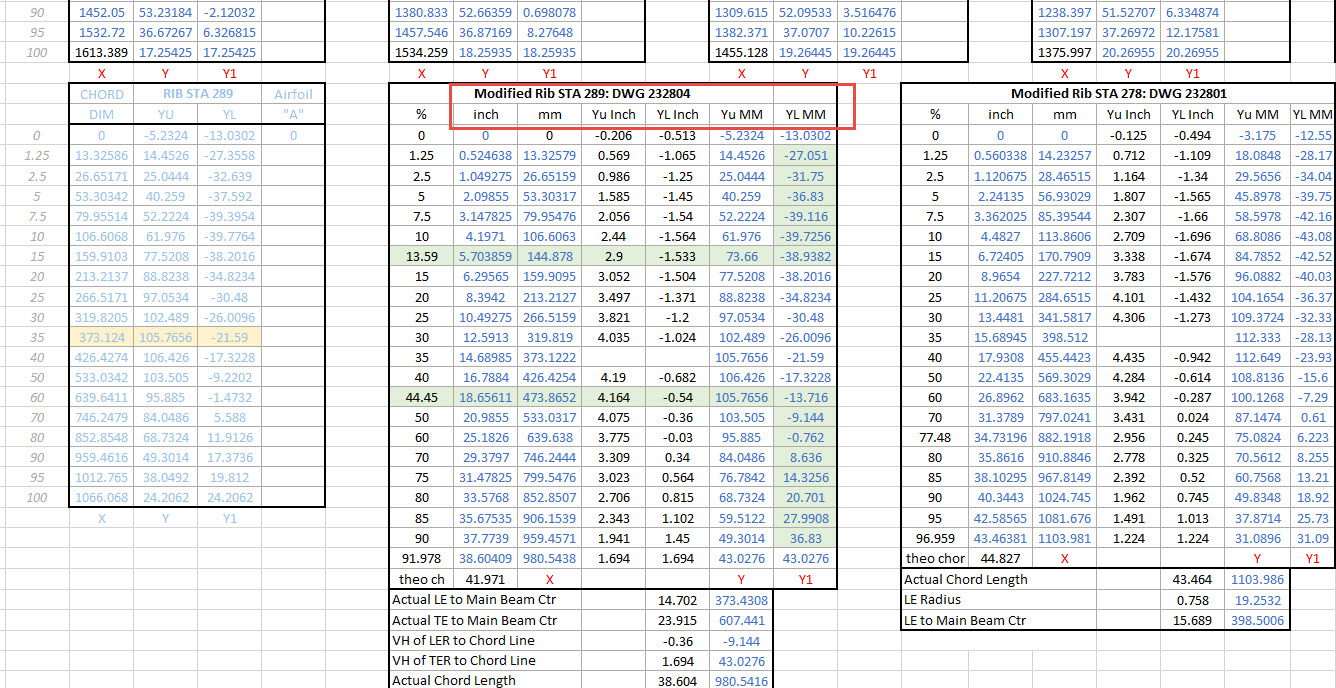

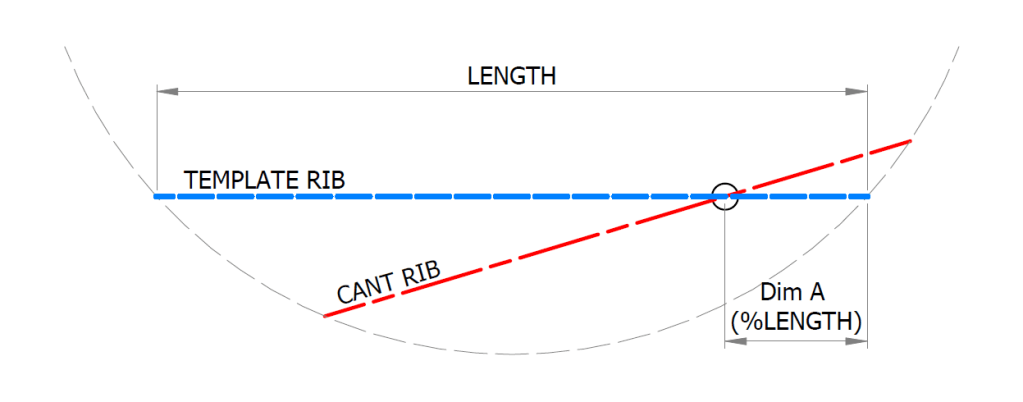

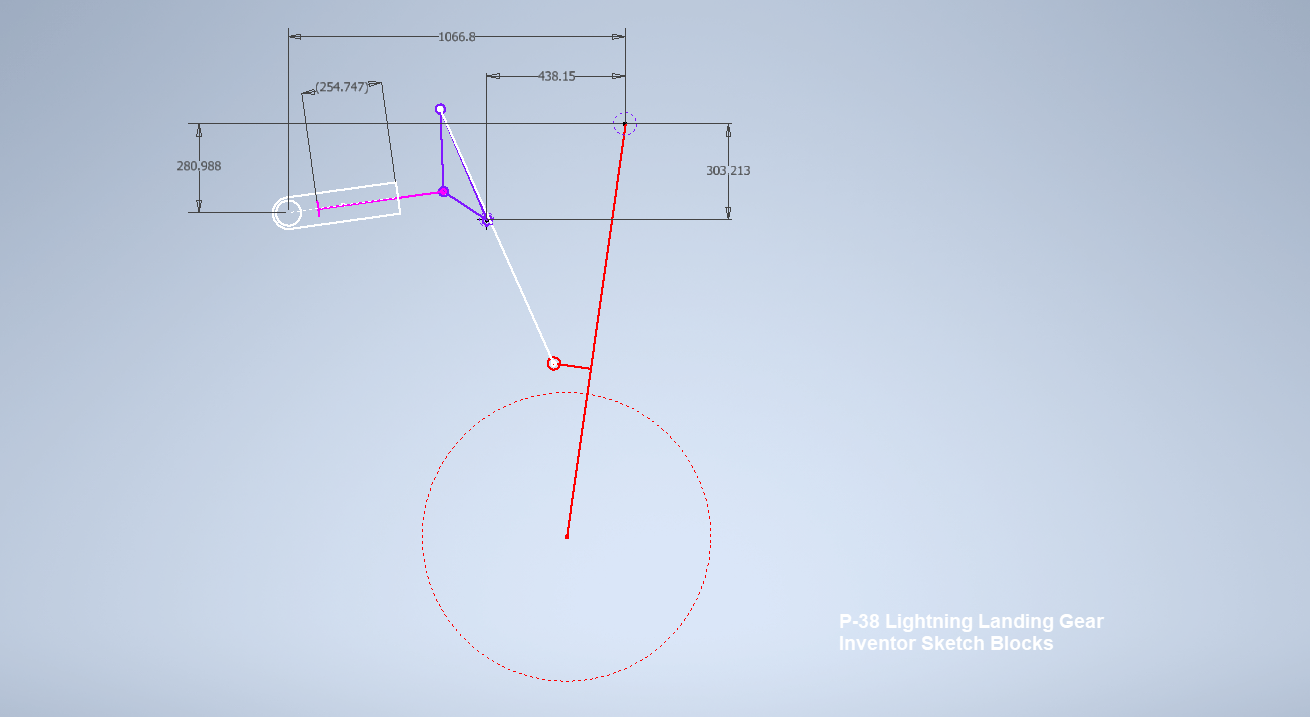

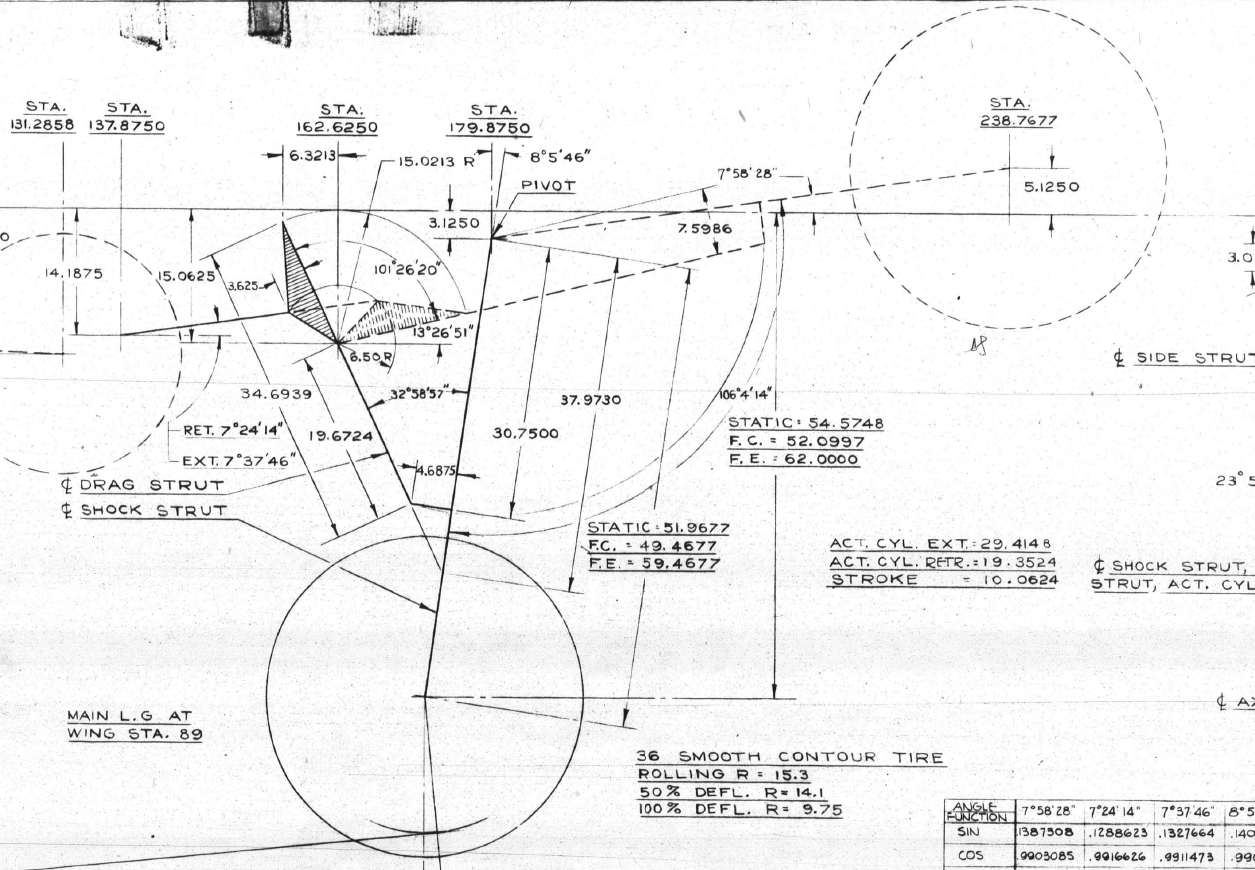

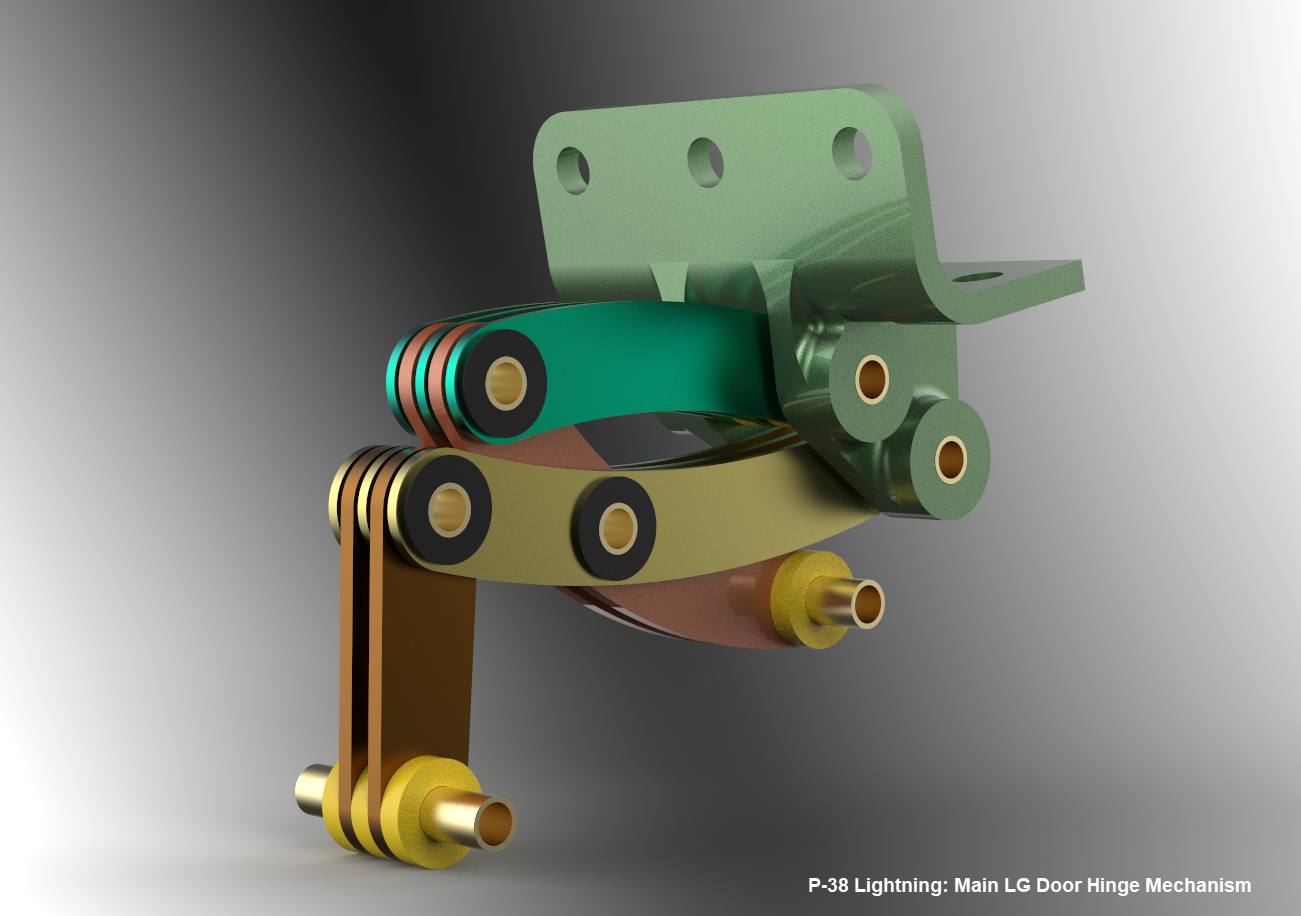

Wing Rib Ordinate Check: As mentioned above I have now carried out a check on the wing rib profile ordinates. Normally I would do this the same way as I calculated the wing rib ordinates for the P-38 Lighting but that is only applicable when you know for certain the root and wing tip rib profiles. The main point of this exercise was to determine the accuracy of the FM2 wing tip profile which is apparently different from the stated NACA 23009 profile.

I resolved to do this using Linear Regression Analysis from plotted points on the 15%, 25%, 50%, and 60% chord planes. These percent chord planes actually have to be determined separately because the wing rib ordinates on the Grumman drawings are incrementally spaced at 2″ and 4″ intervals which of course does give us the straight-line projections we need.

Typically I did this for the top and lower ordinates recorded from each rib at each chord plane and compiled the resulting data into a table in Inventor which was then exported to MS Excel for analysis. The analysis confirms that the wing tip profile is accurately drawn and the ordinates on the drawing profile are correct. I shall also do a similar exercise to check the dimensions of the main beam at the flap and ailerons.

Drop me a line for further information at hughtechnotes@gmail.com

Please consider making a small donation, every contribution makes a real difference.