P-38 Lightning: Looking for Mold Line Drawings!

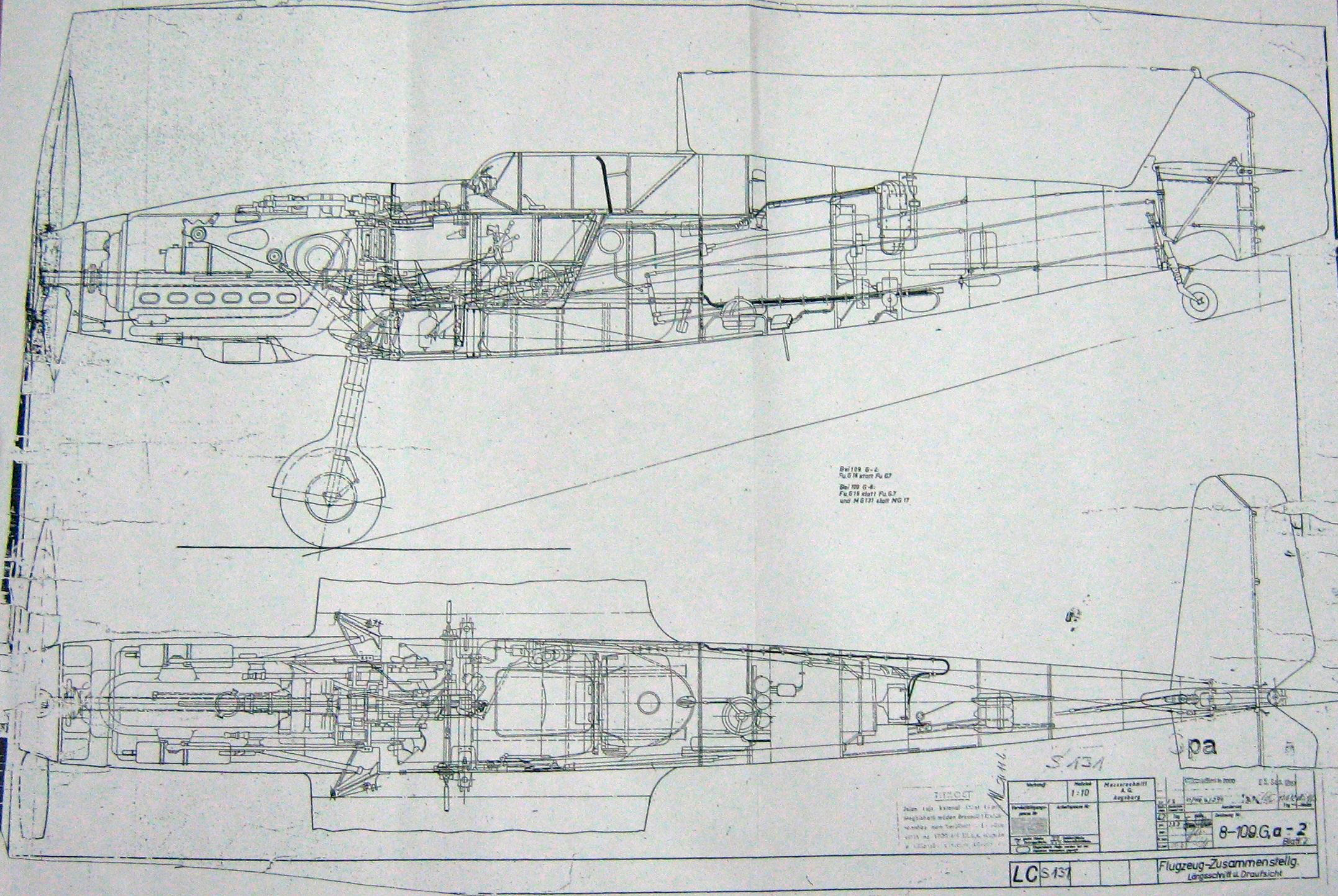

I am looking for 6 Mold Line drawings for the P-38 Lightning. These drawings are the Cowl Mold Lines for the engine encasement.

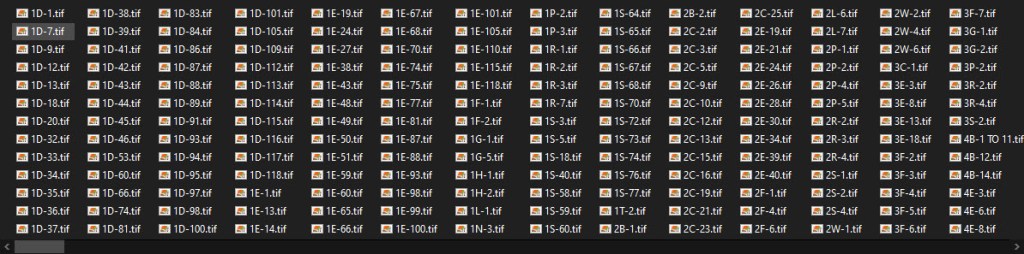

Lockheed drawing numbers: 195072, 195081, 232543, 232544, 232545, 232764.

I can obtain a small number of key dimensions from the panel drawings which will not be enough to achieve an accurate full profile. I do hope someone has a copy.

I have tried all the usual sources for this information without success.

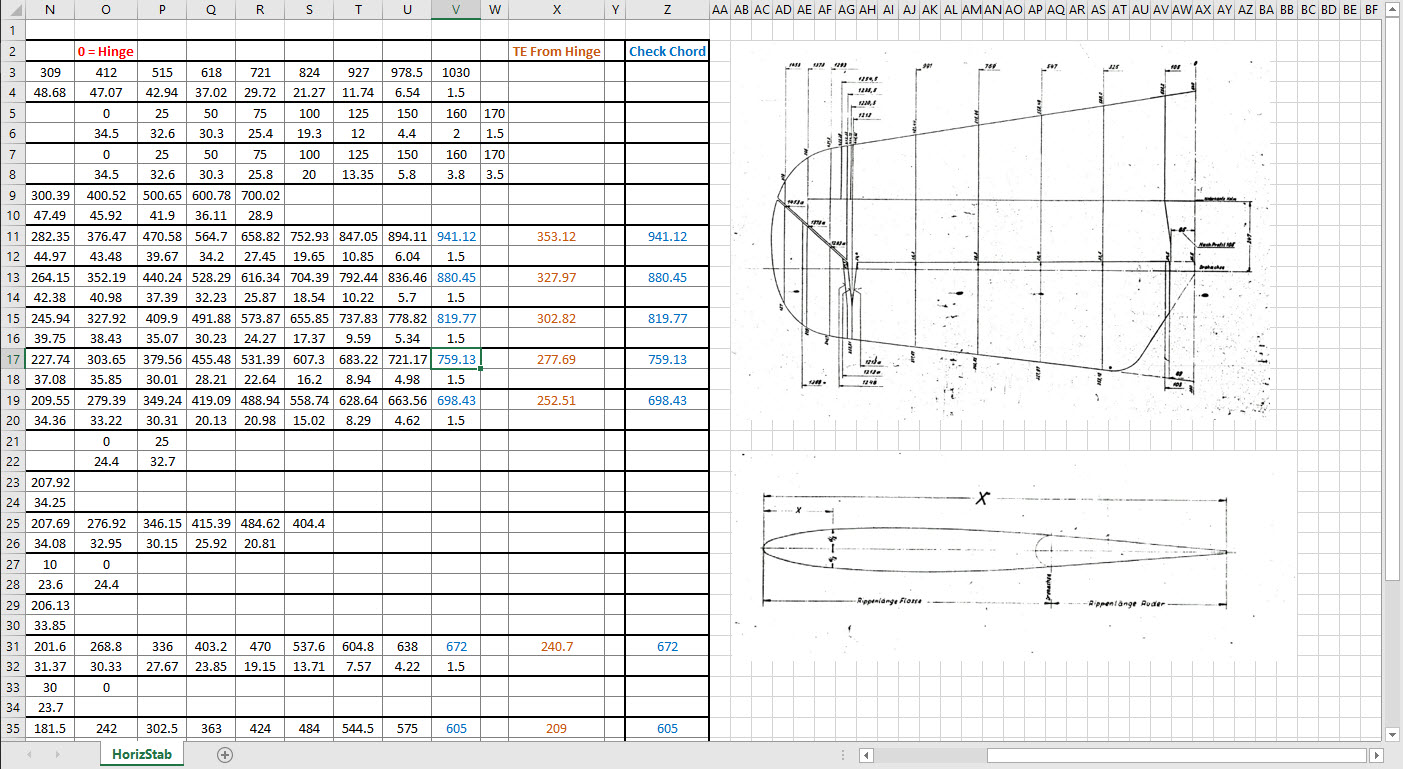

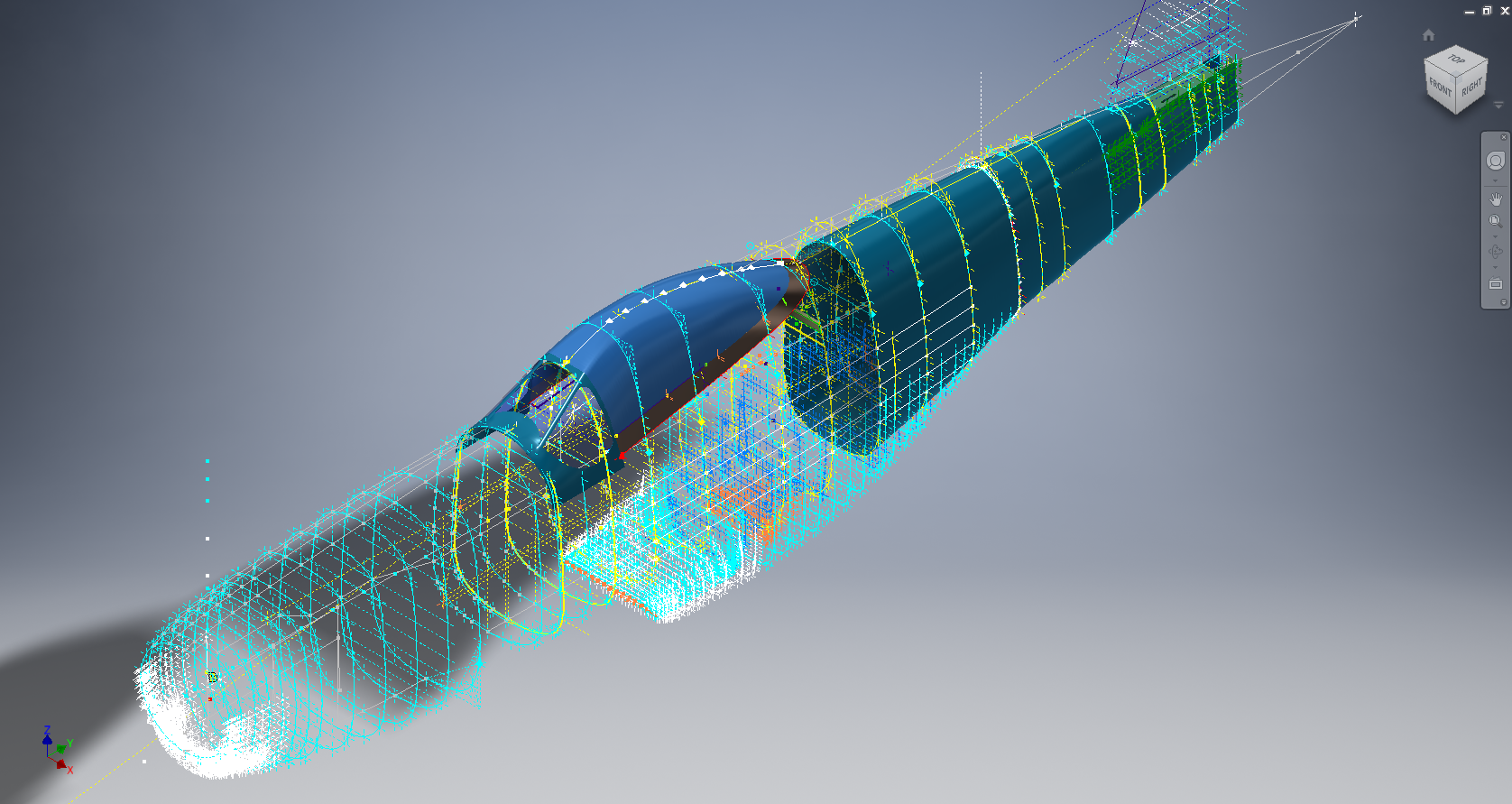

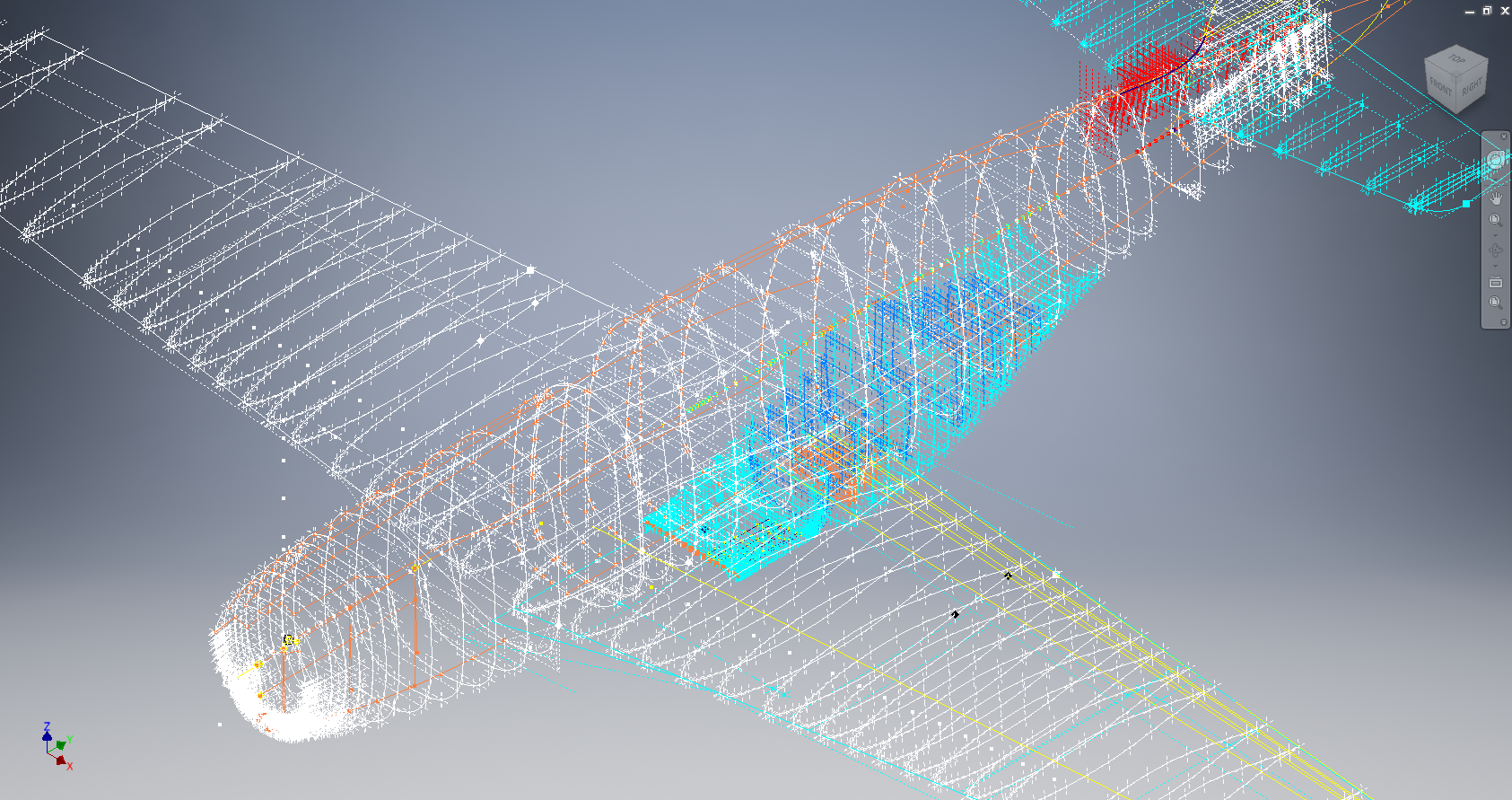

I can’t offer you much for the drawings but I am willing to share the comprehensive ordinate study and cad material when this project is complete.

Further Request: Photos of Wing Tip Required:

The wingtip trailing edge has a tab extension as a consequence of the connection of the top and lower panels. I am curious as to how this extension integrates at the extreme tip of the wing. If anyone has any close-up photos for the wing tip I sure would appreciate a copy.

Let me know if you can help. Email hughtechnotes@gmail.com

Update: 21st May 2022:

I have not had much luck with sourcing the above material. The Mold drawings would certainly have been enormously helpful in determining an accurate ordinate model. There is a Plan B, though it is going to be a fairly intensive search for every morsel of information that can be gleaned from the individual part drawings, manuals and reports that collectively will give me enough to achieve an accurate definition of the FWD Boom and Engine cowl surfaces.

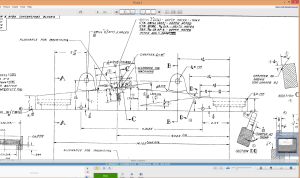

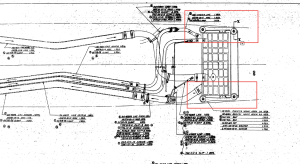

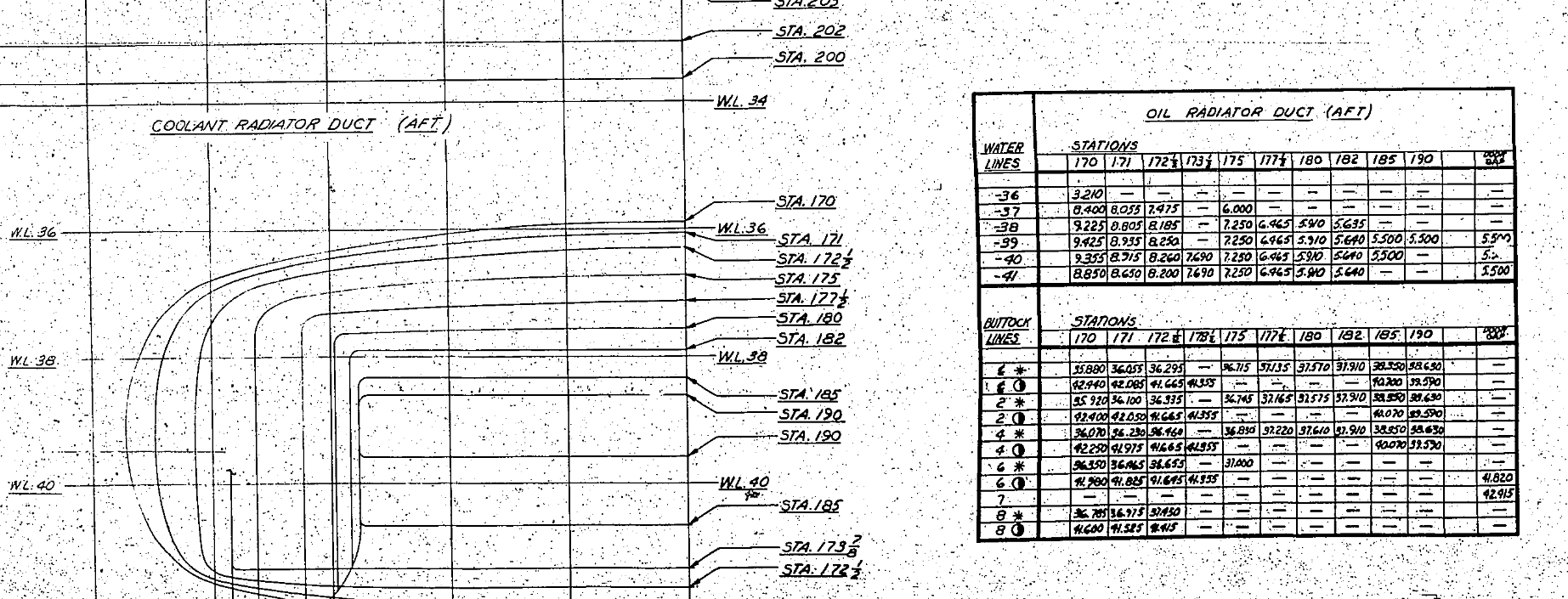

An example would be the Scoop web plate profiles shown above to achieve some surface definition in those areas. I am currently working on the Landing Gear doors which will help define the lower surfaces. This is a lot of work which unfortunately means this will not be ready until much later in the year. I don’t do guesswork, if the ordinate point does not exist it is not on the model.

If anyone has any information that can assist me with these ordinate points, please, please do get in touch.

102-00005: Fuselage (BC main)

102-00005: Fuselage (BC main)

Technical drawings, detailing the specifics of your design can be critical for the communication both internally and externally. We can transform your 2D CAD or fully dimensioned legacy paper drawings to 3D Models using our experienced engineers to ensure drawings are 100% accurate and adhere to the most relevant standards and protocols.

Technical drawings, detailing the specifics of your design can be critical for the communication both internally and externally. We can transform your 2D CAD or fully dimensioned legacy paper drawings to 3D Models using our experienced engineers to ensure drawings are 100% accurate and adhere to the most relevant standards and protocols.