Today with the introduction of computers and CAD design/draughting systems we take it for granted to be able to print pristine copies of the CAD drawings on demand with every copy being of excellent quality.

Up until the late 1980s in fact even into the early 1990s manual draughting on a drawing board was the mechanism by which we developed manufacturing and design drawings.

In consideration of some comments I have read on newsgroups I thought it may be prudent to cover some aspects on the working life of a typical manual drawing, something that is often not fully understood. Through the course of a typical project development; particularly with aircraft; details do change – you just need to look at some of the more common aircraft and see how many variations there is. For every variant and modification usually existing drawings will be updated and new ones created only when required which eventually impacts the quality of the original drawing sheet due to continuous reuse. The luxury of redrawing is not practical in terms of cost and meeting time line objectives….as long as the drawing remains legible it will be reused.

Manual draughting by definition is very different from what we do with CAD drawings – for a start you are working on one drawing sheet at a time, more recently a transparent sheet specially formulated for the purpose. Before you even start the drawing you need to know exactly how it is going to be laid out and where everything will be detailed, because you are only going to do this once – a real skill that would present a real challenge to anyone that has only ever used CAD systems. Reusing the drawing; as mentioned above; for updating design and specifications often required erasing of details and reworking the original drawing – which if you have not tried it, it is not an easy task.

The comments I refer to are from those that complain that copies of original blueprints/drawings currently available from various sources are of suspect quality !!!!

Now lets just think about this for one minute – a lot of drawings were done in wartime conditions, manufacturing design changes were often rushed through the system, there was no such thing as CAD as well as the fact they were originally created over 70 years ago!!

Also bear in mind that in a lot of cases the only existing records of the original manufacturers drawings are microfilm records. Copy film or microfilm during the war years and beyond into mid 20th century was not a stable product for long term archiving which is one reason why organisations spend substantial amounts of money every year restoring these original films and rerecording onto more stable substrate. One other point worth noting is that when the original microfilm records were created they did not always have access to the original drawing sheets and accordingly may only have had workshop paper copies to record the data from…which of course is not ideal but nevertheless we should be thankful to have any records at all.

Factor in the fact that often microfilm recording was done in bulk and the operator may not have given the project 100% attention then it stands to reason that a percentage of records will not be clear and pristine!!

Plus even today cost saving is a prime incentive and often scans from microfilm records will be done in only B&W colour space and not Grayscale. Considering all the above and probably a whole plethora of stuff I have not mentioned then perhaps you can begin to understand why a small percentage of pre-war and wartime blueprints/drawings are not quite up to “standard”.

So the next time someone feels inclined to complain about the quality of historical drawing archive material please think about it for a moment before you post comments.

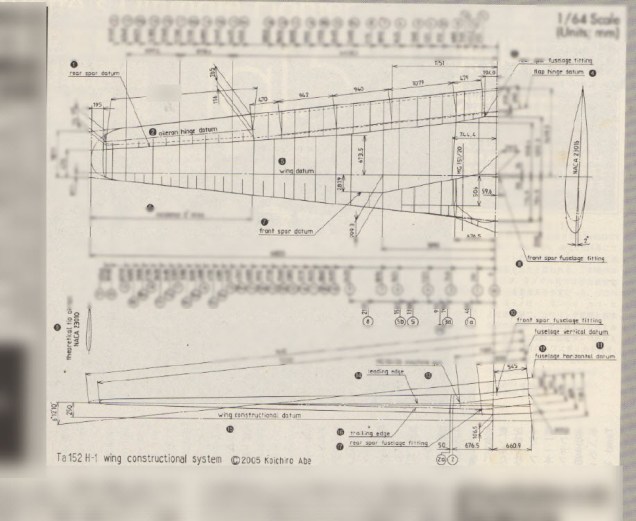

Finally it is worth noting that some enthusiasts like myself are making available Cad drawings (2d&3d) created from some of the less legible material to help others with their projects. This work incidentally is unpaid and countless hours are expended in the necessary research required to develop this material.