P-39 Restoration Project: CAD Services

12 months ago I started providing CAD design services to Planes of Fame, Chino to assist them with the restoration of a P-39 Airacobra. This aircraft is a static display restoration so we had some latitude in the manufacturing of the various parts. This included 3d printing (which is done by a professional company), sheet metal work, and vacuum forming.

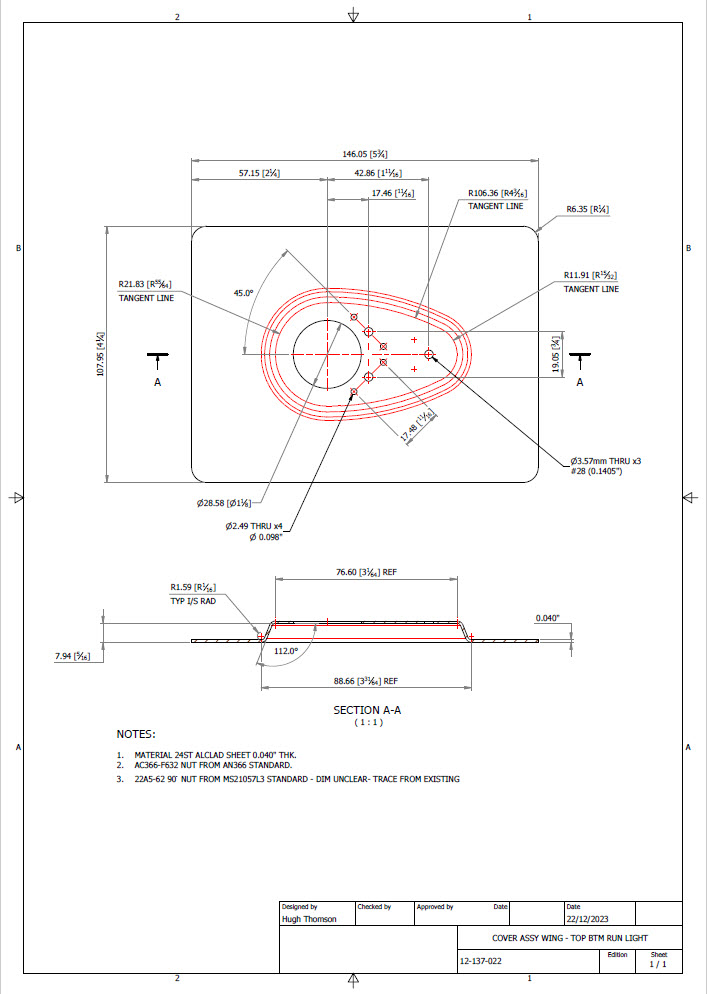

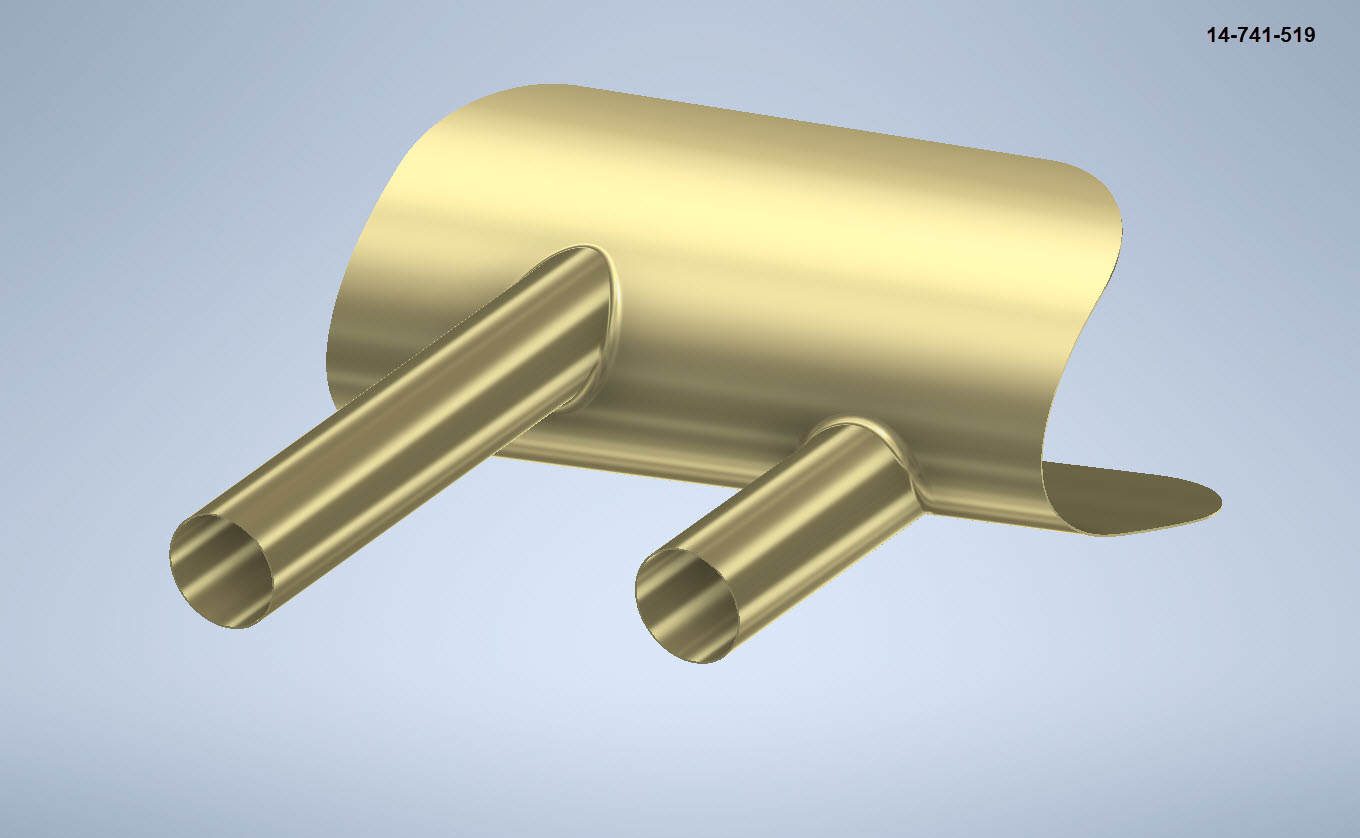

The CAD models generally are for small complex geometry parts as you can see in the examples posted below. When preparing these models everything is double-checked against blueprints and where necessary the aircraft itself to ensure correct profiles.

I have over 40 years of experience in Engineering Design and drafting; in fact, I actually started my career as a draughtsman on the drawing board. I question everything and take nothing for granted with a focus on detail and accuracy. So when I prepare the 3D CAD models I also create a 2D dimension drawing as a checking mechanism to ensure accuracy and also as a reference for the engineers. If the 2D drawing is actually produced specifically for manufacture instead of being a design check it will incorporate all required standards references, tolerances, and material specifications.

3D CAD modeling of parts for aircraft can be quite complex and can take a long time to complete. The smallest part here would normally take about 3 hours. That may seem a lot of time for small parts that appear to be quite straightforward but often it is the reference geometry not visible that takes the time, whether that be the curvature of the wings or fuselage. Then everything is checked and documented.

The P-39 Restoration project still has a long way to go which I feel privileged to be part of.

If you require parts developed in 3D CAD for your project then please don’t hesitate to drop me a line at hughtechnotes@gmail.com.

I would like to take this opportunity to wish everyone a Happy New Year.