Aviation-Inspired Audiophile Solutions: Updated 18th Nov 2025

I’m not sure if anyone is interested in this, but I’ll share it anyway.

For audiophiles, HiFi enthusiasts, and anyone considering upgrades to their audio system. I have developed new product designs that will provide these solutions at minimal costs, inspired by my work on Aviation projects.

Years ago, I had the privilege of helping a start-up company develop their new line of high-end amplifiers. My primary role was designing the amplifier chassis, with some examples shown below.

In addition to the main chassis designs, I needed to think about the feet and how to develop a solution that would provide adequate isolation to reduce vibration and resonance. I spent a considerable amount of time reviewing various commercial options. Some of these designs were excellent but quite expensive, while others honestly lacked proper design input. Like everything else audio related the choices are vast and usually priced beyond the means of the average HiFi enthusiast. This presented a challenge, and these are my solutions.

Speaker/Amplifier Isolation/Anti-Vibration Mounts:

In aviation, there are numerous instances where damping and anti-vibration measures are essential due to the nature of aircraft operations. A clear example is the landing gear, which requires effective dampening. Additionally, damping is important for the installation of instrumentation panels and shock absorption, such as with the tail wheel of the Tiger Moth. This particular case is noteworthy because the innovative design of stacked metal discs interspersed with shock absorber pads inspired my solution, as described below.

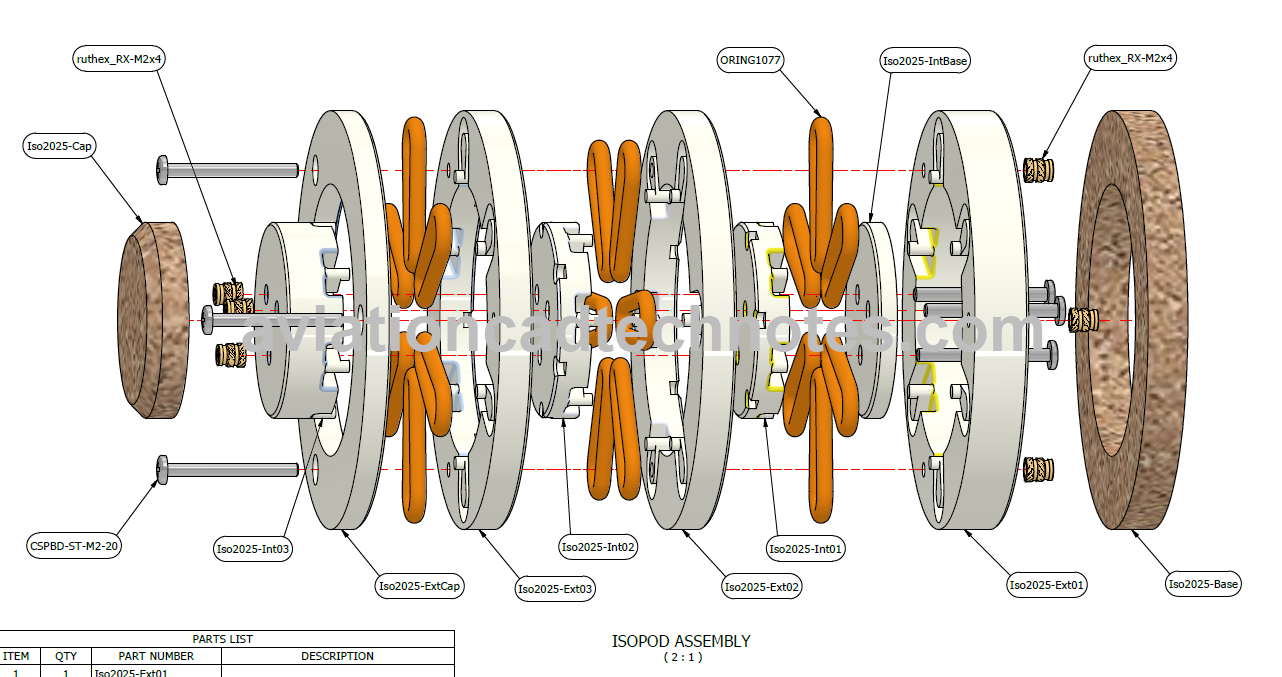

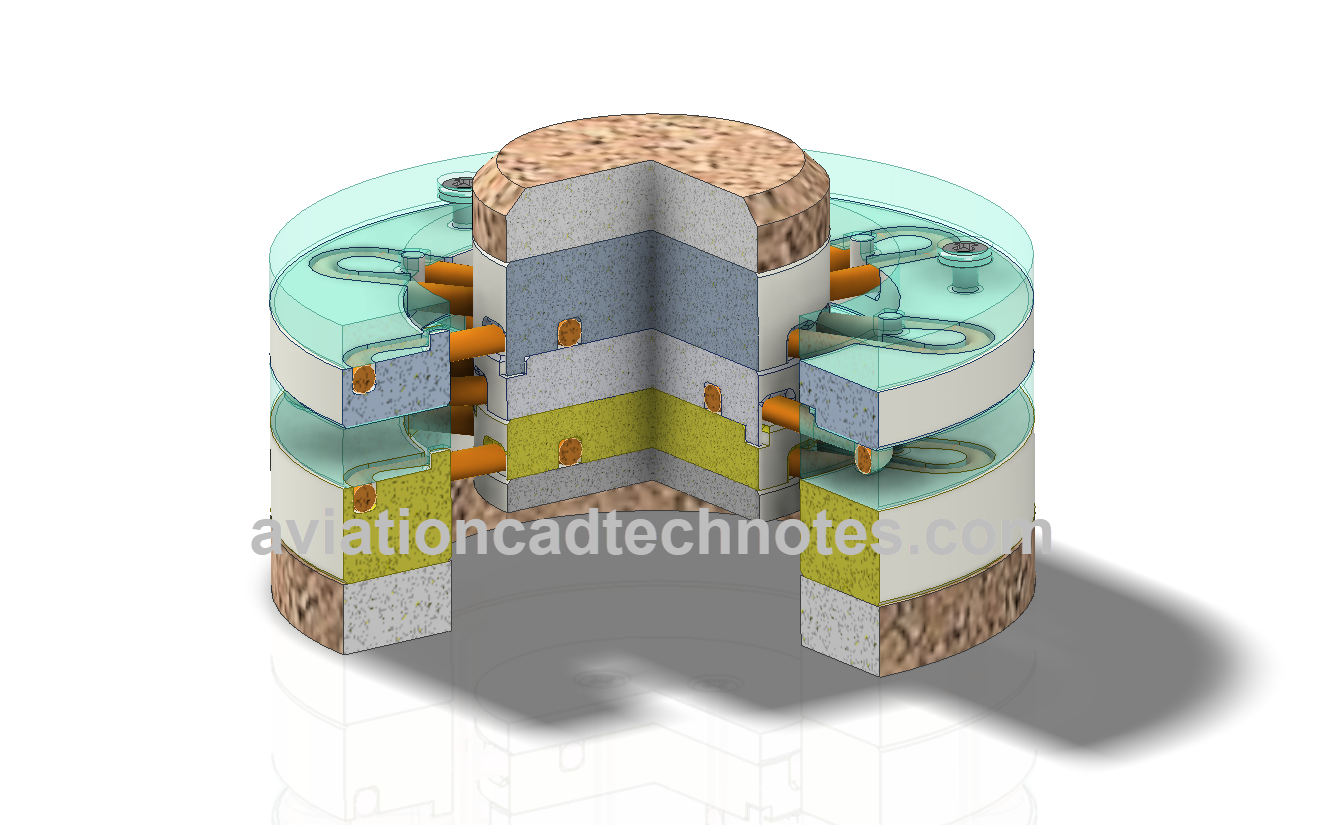

The following images illustrate my solution for an effective Speaker Isolation Mount, which also works for isolating amplifiers (integrated, pre-amp, and power amps) up to 8 kg.

The Isopod-2 is made up of four externally stacked rings and four internally stacked rings, all featuring three layers of silicone o-rings. At the top, there is a composite buffer made from rubber and cork, and the base is constructed from a similar material. The development of this final product took over three years, during which various prototypes were created and tested to achieve this design.

I 3D printed prototypes for all main rings using either standard resin or ABS-Like resin material. I haven’t tested them with alternative engineering resins, but I’m confident they will work well. They are designed so they can be arranged flat on the printer bed and printed without additional support. The size is deliberate to suit even the oldest 3D resin printers out there.

The main purpose of the stacked arrangement is to stabilize the central core and provide sufficient O-rings for adequate load-bearing capacity. The product comes with a series of 2D detailed drawings to assist with assembly, which also provide information about the accessories and fittings.

Check out the Isopod-2 assembly video on YouTube: https://www.youtube.com/watch?v=GWnMh9Ezbbc

Isopod-2 STL, STP, and Parasolid CAD files for 3D printing are available for only £17.50 (GBP). Email me for details. Hughtechnotes@gmail.com

Cable Elevators:

Probably a controversial item, but some serious Audiophiles firmly believe these things can make a noticeable difference. They apparently reduce the effect of vibrations in the floor on your speaker cables.

I’m not completely convinced, and I’ve noticed that many current offerings on the market are excessively overpriced. Just Google it, and you’ll also see that some of these products also lack any design competence.

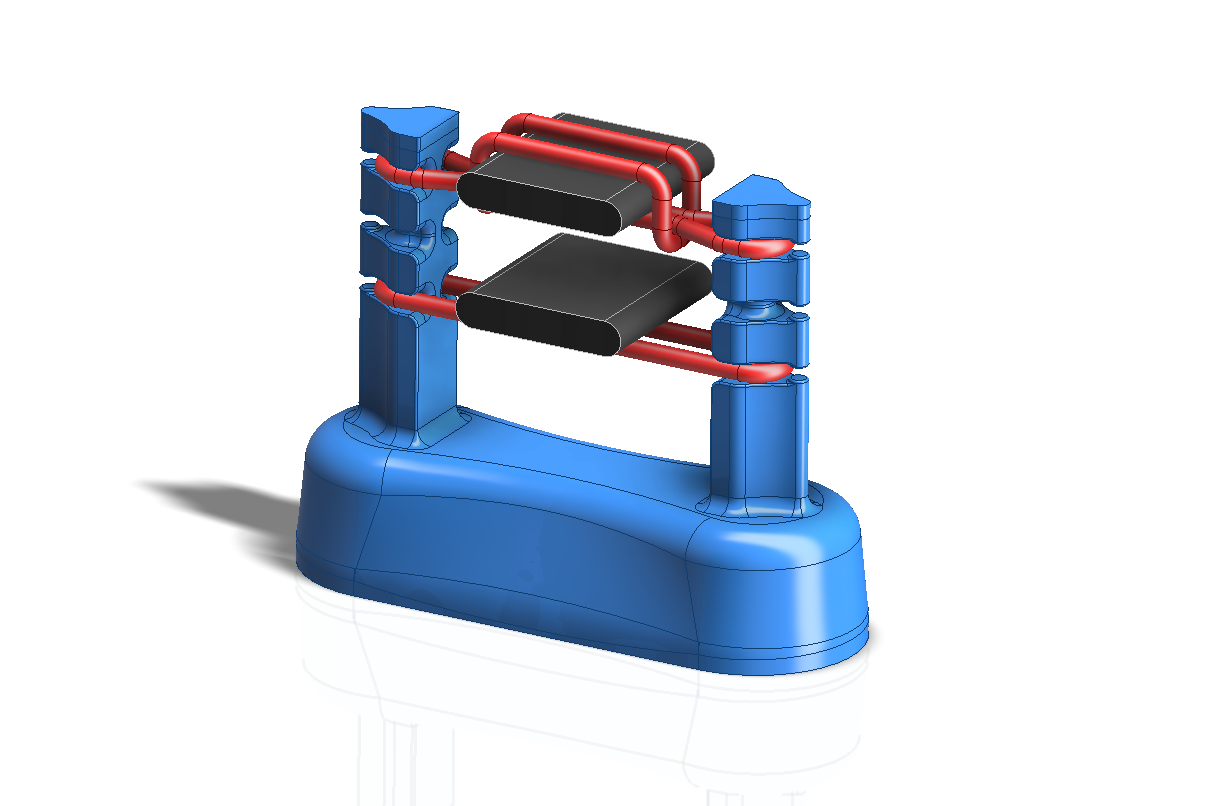

Initially, my original design followed typical industry concepts with improvements to better support the o-rings.

The item on the left is a typical commercial offering with little or no support to help retain the o-rings. I solved this by designing the columns with a small ledge to support the o-rings, making for an easier installation. I can only imagine the slippage with the commercial design whilst installing the o-rings!

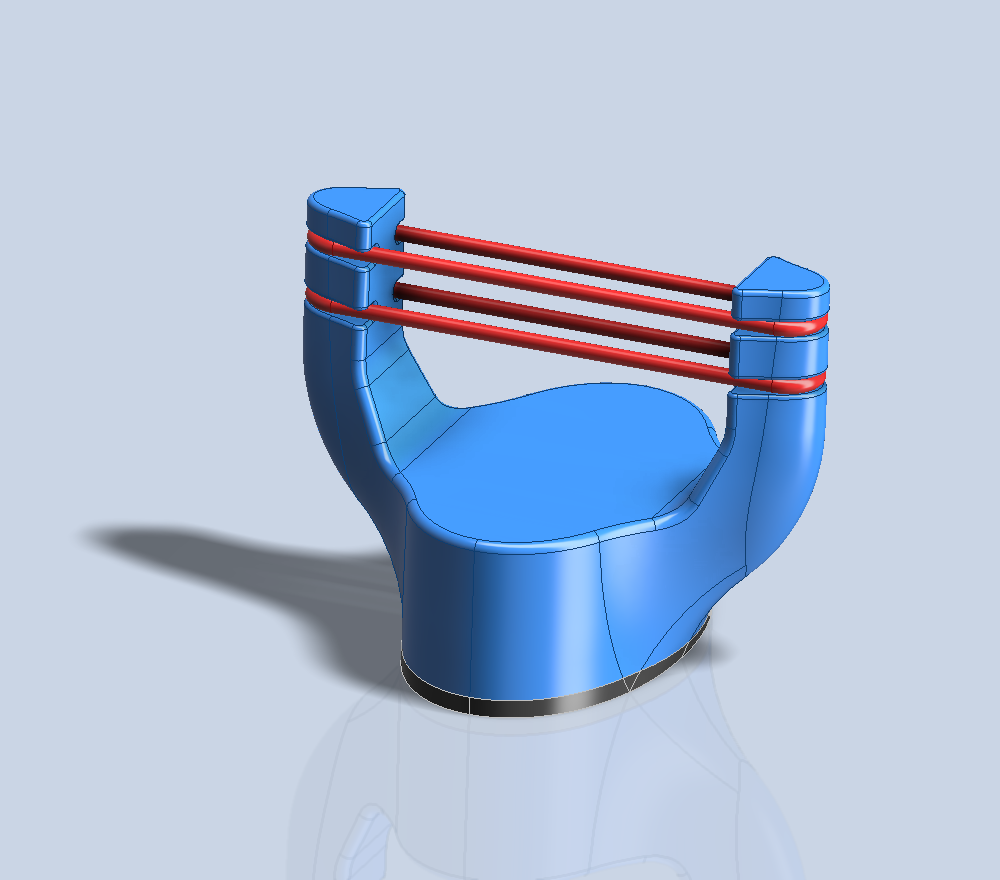

I printed several prototypes of my own design (shown on the right) initially using different resins. However, I noticed a slight bending of the columns when the O-rings were tensioned (<1mm). To address this issue, I added a gusset and printed this time in PLA+ on an Elegoo Centauri, which greatly improves structural stiffness (<0.3mm). Alongside this, I created the more sculptured Elevator, inspired by the Tailwheel Spindle for the P-51.

I now have 2 variations on the Cable Elevator design, both of which feature a void in the base for ballast…perhaps something like Liquid Gravity. In both cases, the design also incorporates custom printing supports, as shown in Yellow in the following images. I plan on doing a new blog post on Custom Supports and how they can be used in conjunction with standard slicer supports, so watch out for that.

I highly recommend printing this on an FDM printer, such as the Elegoo Centauri, using PLA or PLA+.

STL, STP and Parasolid CAD files are available for both designs for a small one-off cost.

Cable Elevator STL, STP, and Parasolid CAD files for 3D printing are available for only £17.50 (GBP). Email me for details. Hughtechnotes@gmail.com

Note: At the time of writing, a Registered Design application has been submitted with the Intellectual Property Office.